How Machinery is Used in Custom Injection Molding

When we hold plastic parts in our hands, we usually aren’t thinking of how it was manufactured or what machines were used in the process.

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

Plastic molding machines are integral to modern manufacturing, converting raw plastic into finished products using a combination of heat, pressure, and motion. They facilitate the mass production of precise, consistent components for a diverse array of industries. For a leading manufacturer like Pioneer Plastics, a deep understanding of each machine component isn’t just a technical detail—it’s the key to enhancing troubleshooting, process optimization, and innovation.

This guide, tailored for manufacturing professionals and enthusiasts alike, will explore each critical element of these machines, explaining its role, mechanics, and importance. By the end, you will have a clear understanding of how these components work together to produce high-quality plastic parts.

Plastic molding technology has widespread influence across diverse sectors and industries. From medical devices to consumer electronics, here are a few real-world examples that highlight the versatility and impact of plastic molding:

These applications demonstrate the adaptability of plastic molding machines to meet demanding industry specifications. By leveraging robust machine components, refined process controls, and a strategic approach to material selection, manufacturers can design and produce a wide array of products that meet both customer requirements and industry regulations.

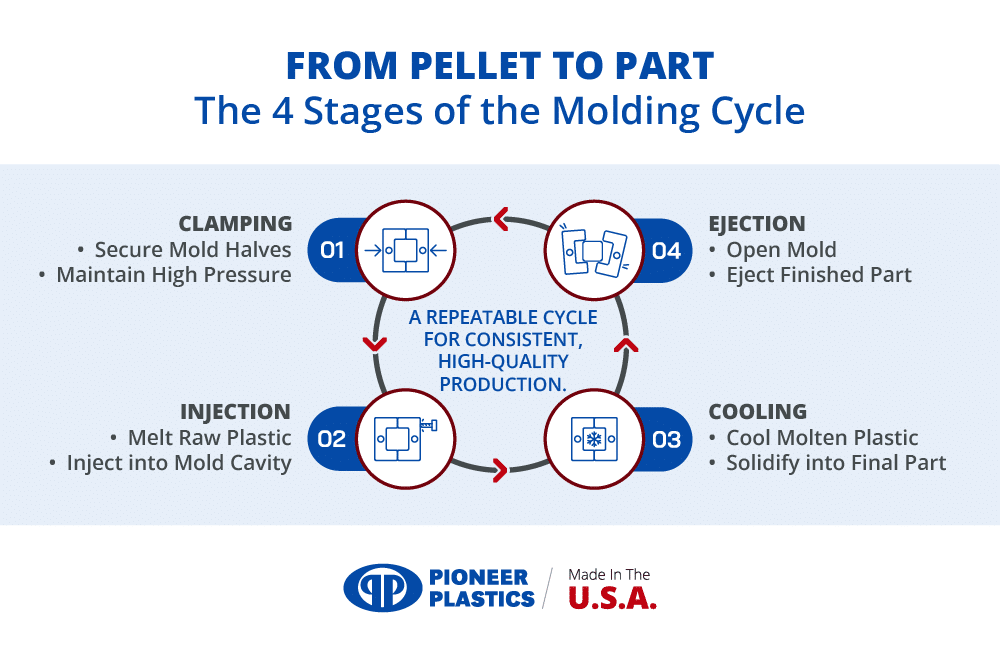

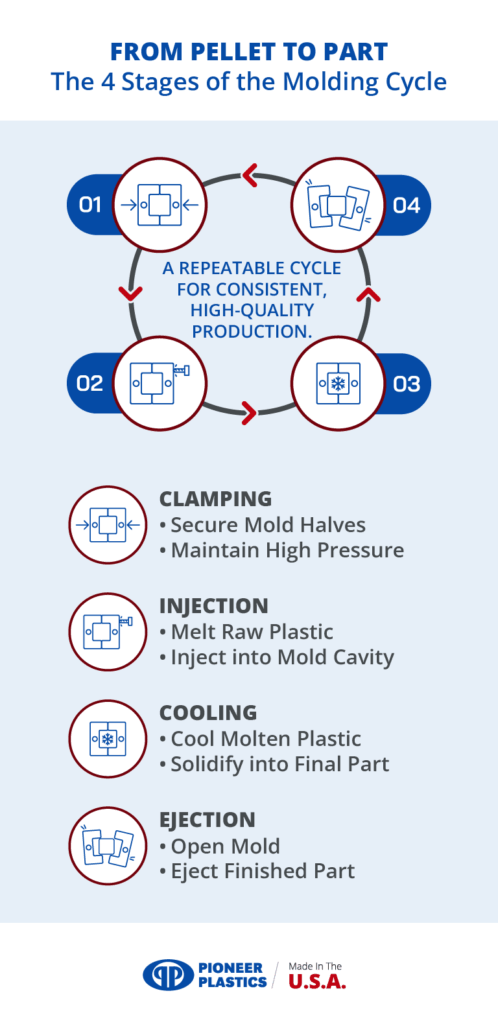

Injection molding is the most widely adopted technique because of its precision and the ability to create complex parts in high volumes. In simple terms, injection molding involves:

Additional molding methods include:

While each process has unique aspects, the underlying principles—precise control of temperature, pressure, and cycle times—remain common. This understanding is foundational when examining the specific machine components that enable each technique.

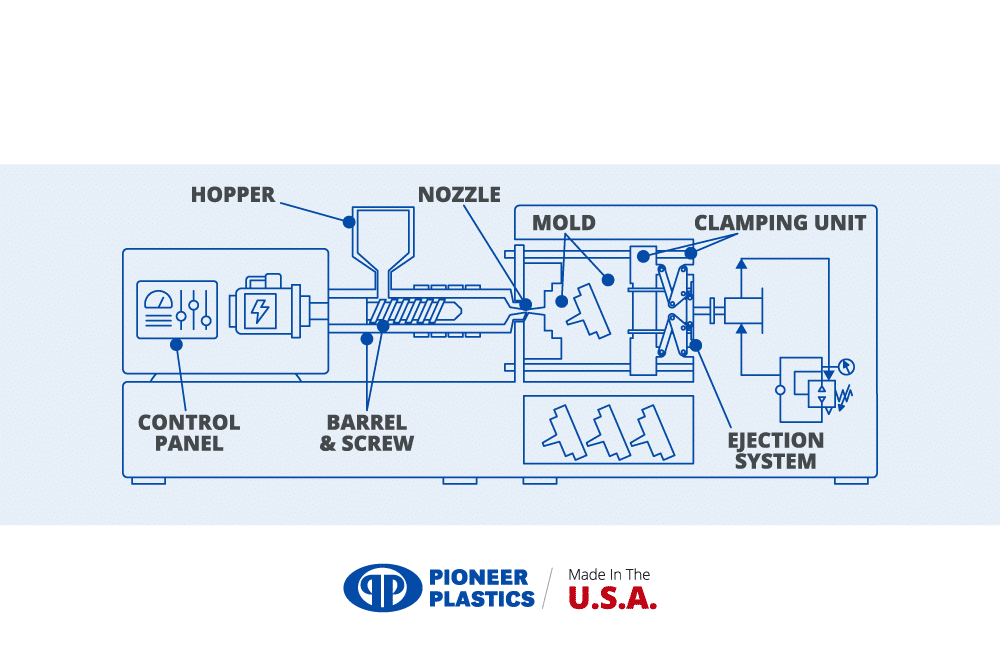

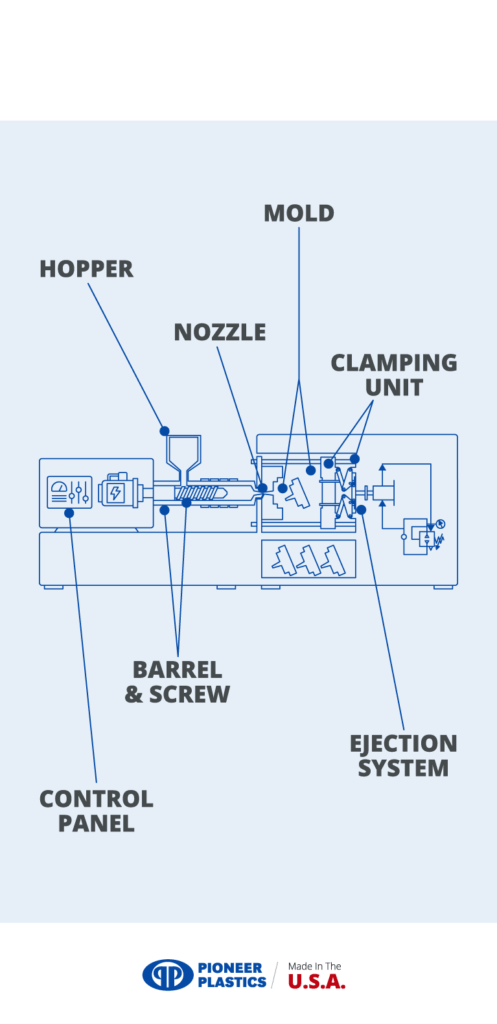

To truly understand a plastic molding machine, it’s best to think of it not as a list of parts, but as a collection of integrated systems working in harmony. We can break down its anatomy into three functional groups: the foundation that provides stability, the core that transforms the material, and the systems that power and control the entire process.

The structural foundation of a plastic molding machine is all about providing stability and managing immense forces. These components form the rigid skeleton that ensures every other part remains in perfect alignment, resisting the pressures of injection and clamping to guarantee precision and repeatability.

The frame and base form the structural foundation of a plastic molding machine. They ensure:

For advanced manufacturing settings, CNC machining for injection mold tooling can significantly improve frame compatibility with various production demands. A well-designed frame directly influences product quality, as even minor misalignments can lead to significant defects.

The clamping unit is essential in keeping the mold halves securely closed during injection. This section explains the key elements:

For certain specialized projects, proprietary plastic products benefit from carefully calibrated clamping systems to prevent flash and preserve mold integrity. A properly calibrated clamping unit also reduces cycle time by securing the mold quickly and efficiently.

At the heart of every molding machine is the system responsible for converting raw plastic pellets into a finished product. This core group of components works in concert to melt, shape, and solidify the material with exceptional control, directly defining the final part’s quality, appearance, and structural integrity.

The injection unit is where the raw plastic is transformed into a molten state ready for shaping. This process involves:

Key process controls include temperature regulation to maintain consistency and pressure management to ensure uniform injection.

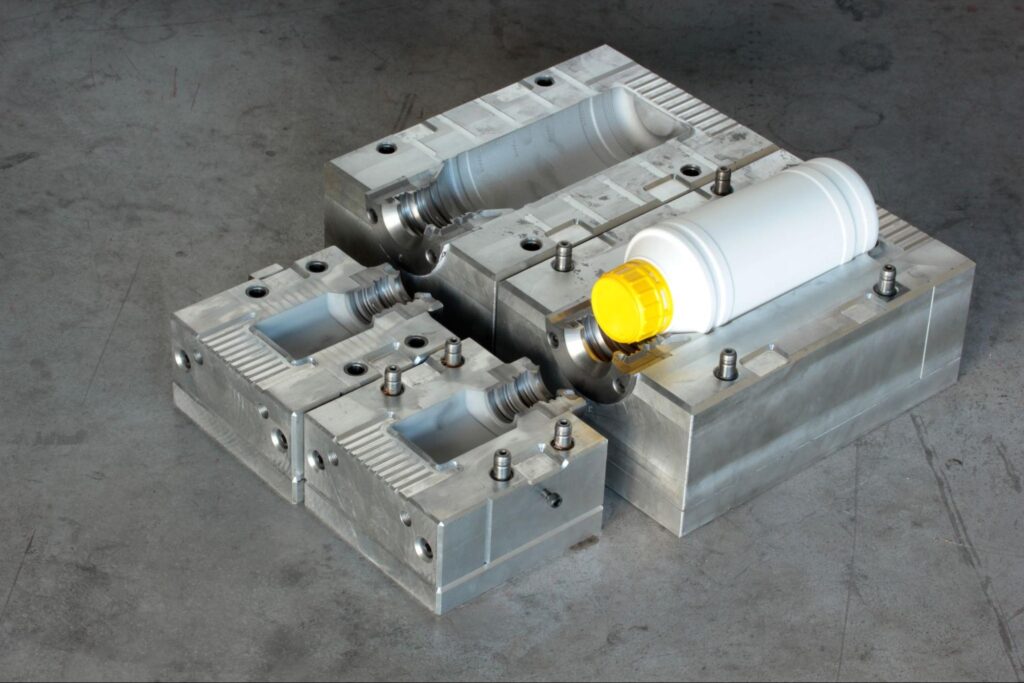

The mold defines the ultimate shape and features of the plastic product. Molds typically include:

Employing engineering services for plastics can streamline the design of complex molds, using Computer-Aided Engineering (CAE) tools to simulate material flow and optimize cooling paths. A high-quality mold directly impacts the final product’s consistency and surface finish.

Precise temperature control is vital in plastic molding:

Advances such as conformal cooling channels allow for even more efficient cooling by following the contour of the mold, ensuring every part of the plastic cools uniformly.

If the foundation is the skeleton and the core is the heart, then these systems are the machine’s brain and muscles. They provide the power, intelligence, and orchestration needed to execute the molding cycle with precision. From driving motion to managing complex process parameters, these components ensure every step happens exactly as programmed.

The evolution of power systems in plastic molding machines has led to two dominant technologies:

These technologies are applied strategically depending on production volume, part complexity, and speed requirements.

The control system orchestrates the plastic molding process by managing key operational parameters. Modern control systems feature:

By integrating these technologies, control systems contribute to improved product quality and reduced waste.

Once the plastic has cooled, the ejection system carefully releases the finished part. The components involved are:

Beyond the machine’s hardware, successful and responsible plastic molding hinges on two factors that every operator must master: the material fed into the machine and the safety protocols surrounding its operation. The right material selection is the foundation of product quality, while a robust safety culture protects the most valuable assets: the personnel and the equipment itself.

Choosing the right plastic is as important as the machine components themselves, affecting the entire process and the final product’s quality. A methodical approach is essential:

A disciplined approach to material selection can dramatically improve product reliability and performance while also addressing sustainability and cost efficiency.

Modern plastic molding machines incorporate comprehensive safety measures to create a secure working environment. These are not optional features; they are integral to uninterrupted, safe production:

Regular safety audits and comprehensive operator training are essential to ensure these systems are used effectively, maintaining a secure environment where production can continue without interruption.

Today’s plastic molding process extends far beyond the physical machine. It has evolved into a dynamic, interconnected ecosystem where data, automation, and intelligent systems work together to achieve unprecedented levels of quality and efficiency. By embracing this modern approach, manufacturers can shift from a reactive to a proactive strategy, turning production challenges into opportunities for innovation.

In a modern facility, waiting for a machine to fail is no longer an option. The focus has shifted to predictive and proactive care to minimize downtime and extend equipment life.

The integration of automation and Industry 4.0 principles is transforming the factory floor, boosting productivity and enhancing sustainability across the entire production line.

Effective quality control is no longer a final inspection step; it’s a continuous, data-driven process that ensures every part meets stringent standards.

Looking forward, this ecosystem will only become more sophisticated and intelligent, further enhancing efficiency, quality, and sustainability.

Sustainability is a growing priority in plastic manufacturing. Key sustainability measures include:

Embracing best practices in sustainability in plastic manufacturing can help companies meet environmental goals while also reducing costs. These measures align with broader industry efforts to shrink carbon footprints and improve operational efficiency.

Plastic molding machines are paramount to the manufacturing processes. These machines transform raw materials into expertly crafted products using precision engineering and advanced technology. Every component — from the robust frame to the precise clamping unit, efficient injection system, and reliable ejection mechanism — plays a vital role, ensuring high-quality and consistent performance.

Modern manufacturers, such as Pioneer Plastics, understand that the machine is just one part of an integrated production ecosystem. They embrace advanced technologies like data analytics, artificial intelligence, and automation to optimize processes and achieve exceptional results. By embracing Industry 4.0 advancements, they are committed to excellence and sustainability. Contact Pioneer Plastics to learn more about their capabilities and see how they can support your business in achieving high-quality, sustainable plastic molding solutions.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

When we hold plastic parts in our hands, we usually aren’t thinking of how it was manufactured or what machines were used in the process.

In today’s dynamic manufacturing world, finding a production method that is both efficient and adaptable is crucial for meeting unique customer demands. Custom injection molding

DIXON, Kentucky – Pioneer Plastics was selected as Pizza Hut Europe’s Innovation of the Year award recipient for the creation of the Pizza Delivery Stand,