When Designing Custom Plastic Parts, Fit And Function are Important

When designing your custom plastic part, it’s crucial to consider what the part’s fit and function will be. First and foremost, the function of the

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

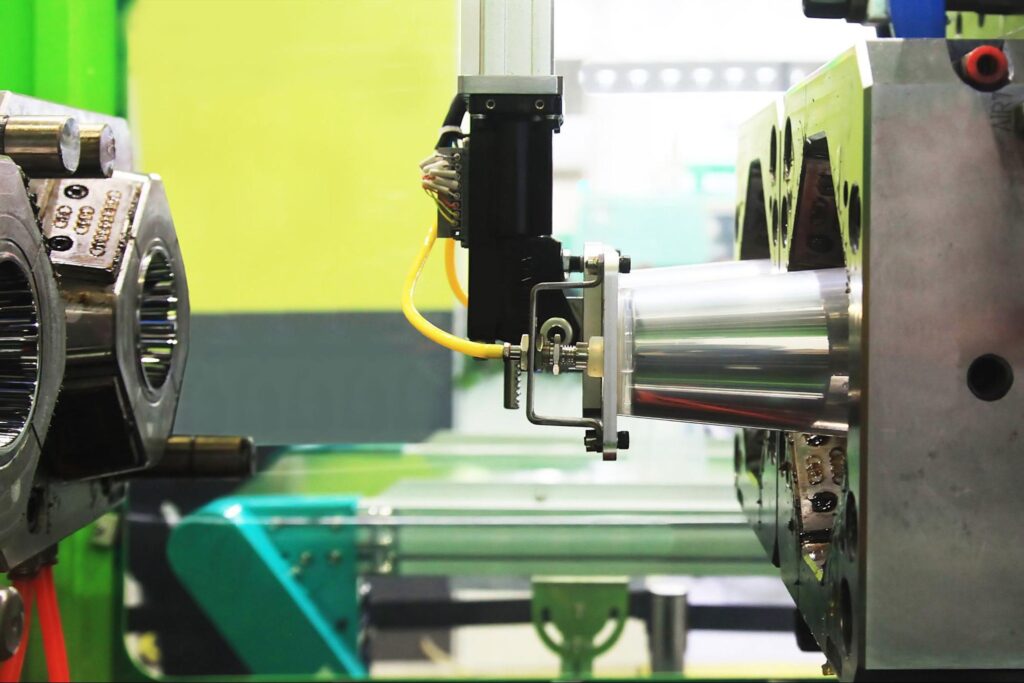

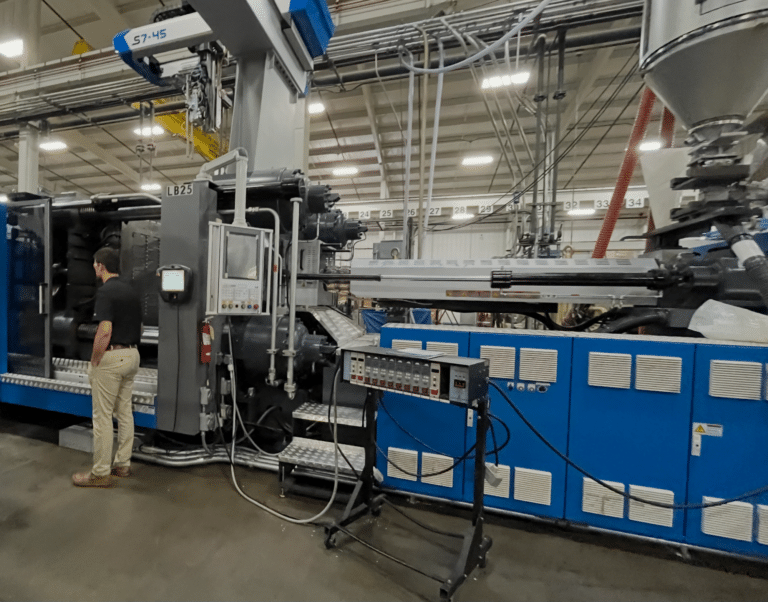

Tooling is the backbone of plastic injection molding. It involves creating molds, dies, and other specialized equipment that transform molten thermoplastic into precise, high-quality components. When tooling in manufacturing is substandard, issues such as warping, shrinkage, and dimensional inconsistencies can arise, wasting materials and delaying production. In contrast, precision-engineered tools improve consistency, reduce waste, and shorten cycle times, thereby lowering production costs and boosting efficiency.

According to recent market analyses, the global injection molded plastics market is valued in the hundreds of billions of dollars, highlighting the extensive scope and demand for effective tooling solutions.

Effective tooling not only drives immediate production improvements but also supports long-term strategic goals. Manufacturers who invest in optimized designs and regular maintenance remain competitive in an industry defined by rapid technological innovation and evolving global market demands.

Successful injection molding begins with a deep understanding of tooling, which encompasses both the intricate design of the mold and the materials from which it is made.

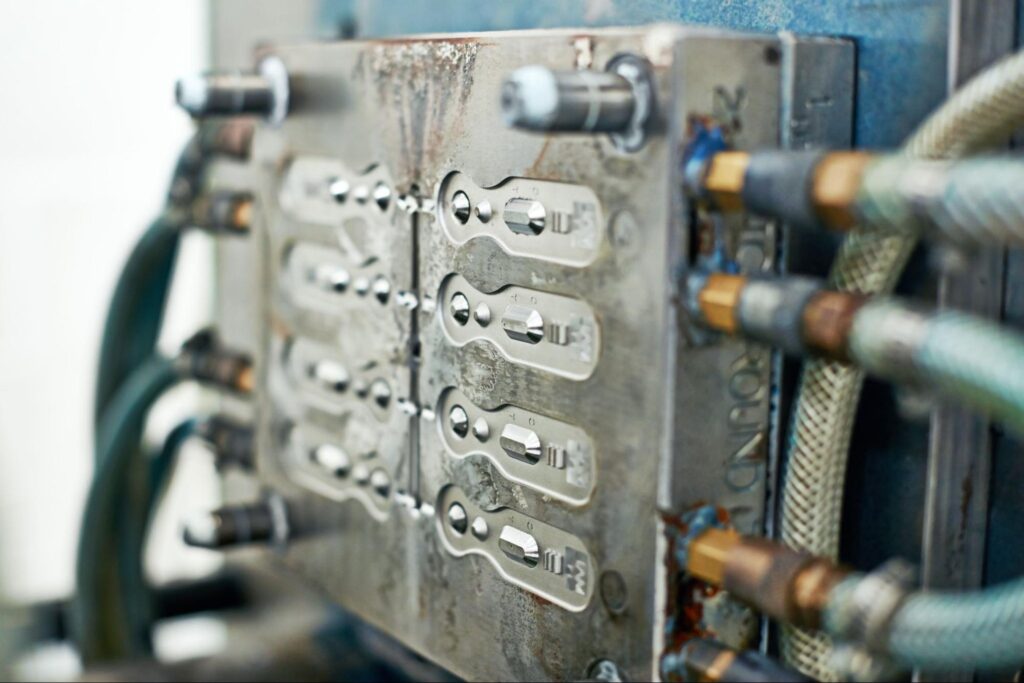

Effective tooling is rooted in a well-engineered mold design. An injection mold typically comprises two halves—a cavity and a core—that together define the final part. Within this structure, several key components work in concert to ensure a flawless molding cycle. These include:

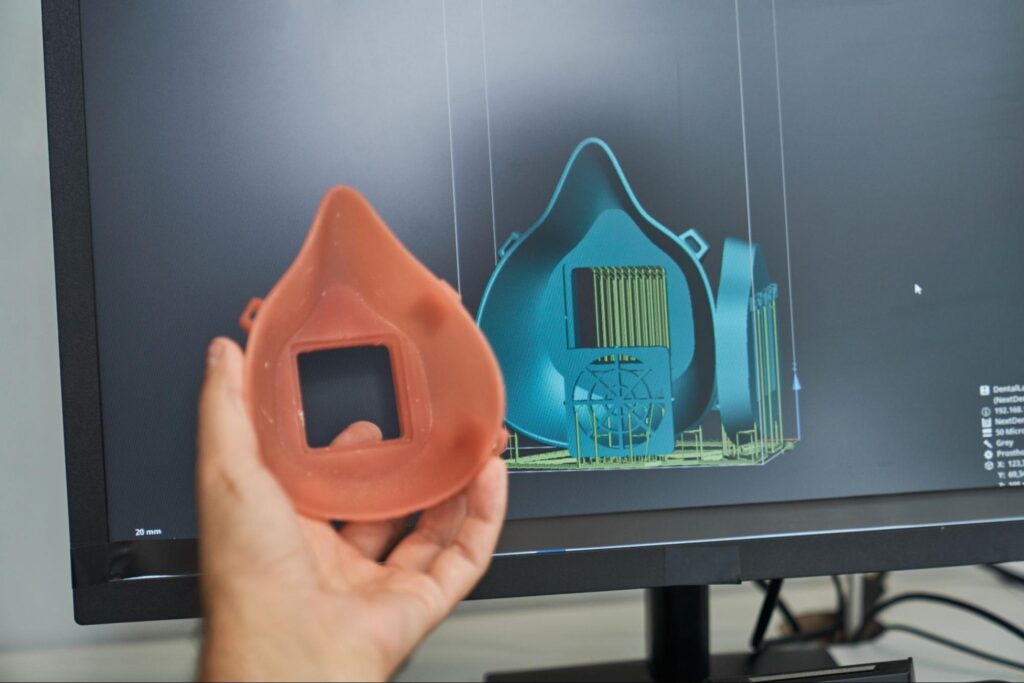

For high-volume production, multi-cavity molds are designed to produce several parts simultaneously, which can increase throughput despite a higher initial cost. Conversely, single-cavity molds offer tighter tolerances with minimal waste, making them ideal for lower-volume production runs. As highlighted by the Society of Plastics Engineers and through modern design methods employing CAD/CAM and simulation software, engineers can test and refine mold features virtually. This digital approach identifies potential issues before physical prototypes are produced, resulting in significant time and cost savings.

Just as critical as the mold’s design is the material from which it is constructed. Selecting the right tooling material is vital for durability and optimal performance. Manufacturers typically choose between:

The final material selection is influenced by production volume, part complexity, resin properties, and budget constraints. A lifecycle cost assessment that weighs upfront expenses against long-term performance ensures decisions align with both economic and technical requirements. Manufacturers must consider how these material choices directly impact production efficiency and the longevity of the tool itself.

Optimized tooling is far more than a technical requirement; it is a core driver of manufacturing success, directly linking production capabilities to profitability and market reputation. High-quality, precision-engineered tooling is the strategic linchpin that enables both exceptional product quality and maximum operational efficiency. These two outcomes are not mutually exclusive—rather, they are intertwined results of a commitment to tooling excellence.

On the production floor, the impact on efficiency is immediate and quantifiable. High-quality molds produce fewer defects, which in turn reduces costly rework and shortens production cycles. Precision tooling facilitates the production of parts with clean edges and accurate dimensions, often eliminating the need for secondary finishing operations. Furthermore, in many cases, tooling designed for automation minimizes manual intervention. Durable molds that are built to withstand high pressures and repeated cycles lower downtime and support consistent, predictable production schedules. Ultimately, these advantages help manufacturers maximize their output and profitability.

Simultaneously, this same precision is essential for producing the superior product finishes and structural integrity that build a brand’s reputation. The quality of the tooling directly influences a product’s final appearance, texture, and performance. Industries with stringent standards—such as those producing medical devices, consumer electronics, and collectible display cases—rely on custom-designed tooling to maintain tight tolerances and achieve exceptional, repeatable results. Advanced tooling allows for rapid iterations and high levels of customization, helping manufacturers meet both rigorous industry standards and evolving customer expectations.

By viewing tooling as a strategic investment, manufacturers can see that efficiency and quality are not a trade-off. Instead, they are dual benefits that stem from the same source. This synergy—producing better parts, faster and with less waste—not only reinforces market competitiveness but also underpins a lasting reputation for excellence.

Tooling in injection molding faces several challenges that can affect production quality and efficiency:

Industry bodies like the Plastic Industry Association emphasize the importance of proper mold design, material selection, and maintenance to mitigate these challenges. Addressing these issues demands a holistic approach that combines precise design, state-of-the-art technology, and a commitment to continuous improvement.

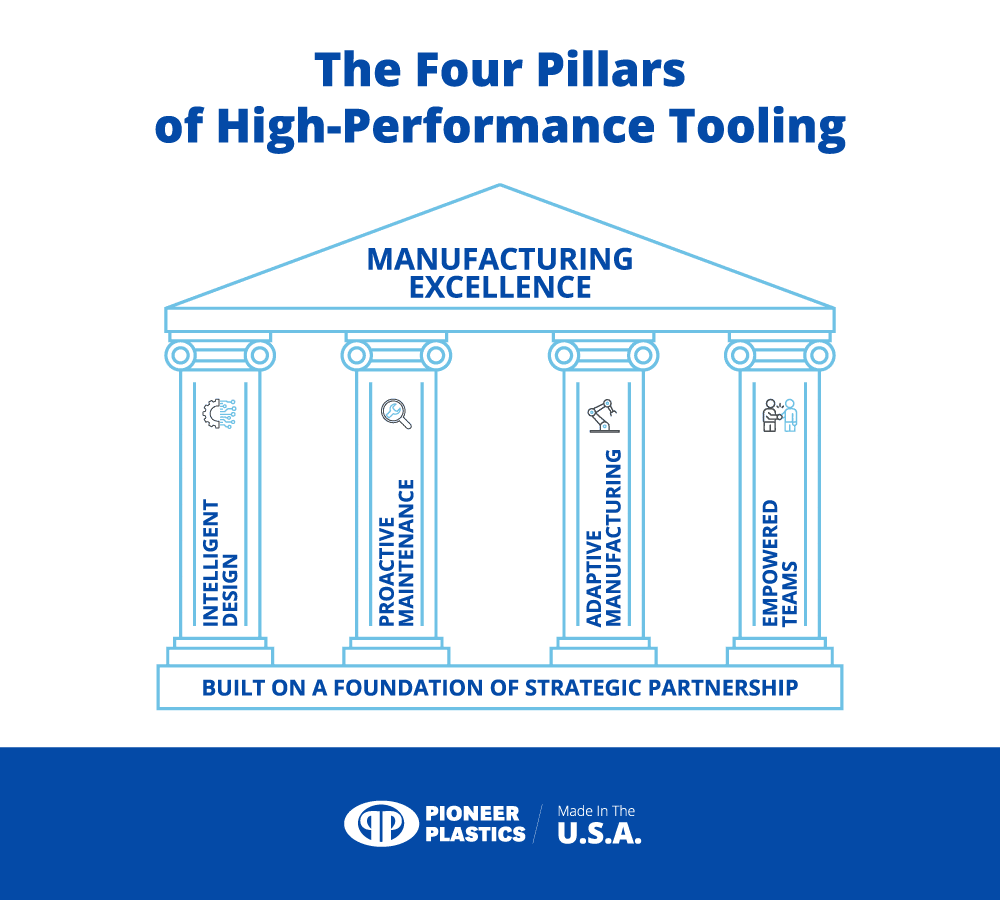

Achieving maximum performance and longevity from injection molding tooling is not the result of a single action, but a commitment to a holistic framework. By integrating best practices across design, maintenance, operations, and personnel, manufacturers can build a resilient and highly efficient production ecosystem. To overcome common challenges and drive continuous improvement, manufacturers should adopt the following strategies:

Utilize CAD/CAM and mold-flow simulation software to create precise digital blueprints. These tools are essential for detecting potential issues early, allowing engineers to optimize critical features like cooling channels, wall thickness, and gate placements before any steel is cut. This virtual testing phase significantly reduces the risk of costly errors and accelerates the development timeline.

Rather than reacting to breakdowns, prioritize a schedule of routine inspections, cleaning, and lubrication. Early detection of wear, pitting, or distortion lowers the risk of unexpected production stoppages and helps maintain consistent part quality. To ensure molds remain within strict tolerances, employ advanced techniques such as Coordinate Measuring Machine (CMM) assessments, laser scanning, and optical inspections. Automating these inspection processes wherever possible minimizes human error and promotes consistent, data-backed quality control.

Simplify product designs to facilitate more efficient and reliable production. Incorporating Design for Manufacturability (DFM) principles means creating molds with straightforward cooling, gating, and ejection features that reduce the likelihood of defects and speed up cycle times. This approach inherently considers how the chosen resin properties will interact with the mold, ensuring a synergistic relationship between material and machine.

In a dynamic market, tooling must be adaptable. Opt for modular tooling setups that can be reconfigured quickly, reducing downtime during product transitions and allowing for swift modifications based on fluctuating demand. For high-volume needs, multi-cavity designs enable the simultaneous production of several parts, dramatically reducing per-unit costs and shortening lead times.

Develop tooling that supports seamless integration with robotic handling or other automated systems. Features such as built-in ejector systems and standardized clamping mechanisms reduce the need for manual handling, which in turn boosts production speeds, improves worker safety, and ensures greater process consistency.

Advanced technology is only as effective as the workforce operating it. An adept team of technicians and engineers is critical for interpreting measurement data and, most importantly, troubleshooting unplanned production issues.

Empower your team with the skills and tools—such as real-time process monitoring—to identify and resolve problems promptly, thereby reducing overall downtime. Foster a culture of continuous improvement through regular training and robust communication between design and production, which ensures that lessons learned from troubleshooting are fed back into future designs and processes.

A critical aspect of tooling is understanding the financial benefits of technology upgrades. Although high-quality tooling demands a significant upfront investment, the long-term returns frequently justify the expense. Enhanced tooling reduces overall production costs by decreasing downtime, minimizing rework, and increasing energy efficiency.

Companies commonly analyze the cost per part produced before and after tooling upgrades to quantify these benefits. Improved cycle times directly correlate with increased production volumes, subsequently boosting revenue generation. Moreover, the enhanced reliability of modern tooling systems ensures fewer production interruptions, resulting in predictable schedules and smoother supply chain management.

Innovations such as AI-driven diagnostics and digital twin simulations refine ROI further by identifying even minor process improvements that culminate in substantial cost savings. Over time, these advancements offer a competitive edge by enabling manufacturers to deliver higher quality products faster and more cost-effectively amid market fluctuations.

The landscape of injection molding is evolving at a rapid pace, moving beyond incremental improvements to embrace a new paradigm driven by data-driven decision-making and digital innovation. The future of tooling lies in creating intelligent, interconnected systems that are more efficient, predictive, and adaptable than ever before. This digital transformation, often called Industry 4.0, is setting new benchmarks for quality and productivity.

Several key trends are at the forefront of this evolution:

As material science and design technologies continue to advance, manufacturers who embrace these digital innovations will be best equipped to meet emerging challenges. Harnessing the power of real-time analytics, predictive maintenance, and digital simulations is no longer a futuristic concept but a practical strategy for securing a lasting competitive advantage in a dynamic global market.

Successfully navigating the landscape of modern injection molding tooling requires a significant investment in technology, processes, and expertise. For many manufacturers, the most efficient way to leverage these best practices is to collaborate with a proactive tooling partner who acts as an extension of their own team.

A true partner, such as Pioneer Plastics, contributes far more than just a physical mold. They provide management of tooling transfers and invaluable strategic guidance at every stage, including:

By engaging with a seasoned toolmaker early and continuously, you transform tooling from a mere capital expense into a powerful competitive advantage. This collaborative approach fuels continuous improvement, mitigates risk, and ensures your manufacturing process is built on a foundation of quality and excellence.

Precision tooling remains fundamental to achieving efficiency, reliability, and superior product quality in plastic injection molding. High-quality tooling facilitates shorter cycle times, reduces waste, and paves the way for automation—key drivers of production excellence and profitability. By embracing advanced innovations such as AI-driven design, digital twin simulations, and predictive maintenance, manufacturers are well-prepared to overcome challenges and thrive in a competitive market.

Transform your production process by partnering with Pioneer Plastics. Contact us today to discover how our custom injection molding and custom-designed tooling solutions can drive unparalleled efficiency, elevate your manufacturing capabilities, and bring your innovative vision to life.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

When designing your custom plastic part, it’s crucial to consider what the part’s fit and function will be. First and foremost, the function of the

Achieving defect-free, high-performing plastic products requires precision and dedication at every production stage. In plastic injection molding, quality control is essential for ensuring that every

Pioneer Plastics, a renowned custom plastic injection molding manufacturer, is located in Dixon, Kentucky. Established with a vision to deliver high-quality and innovative plastic solutions,