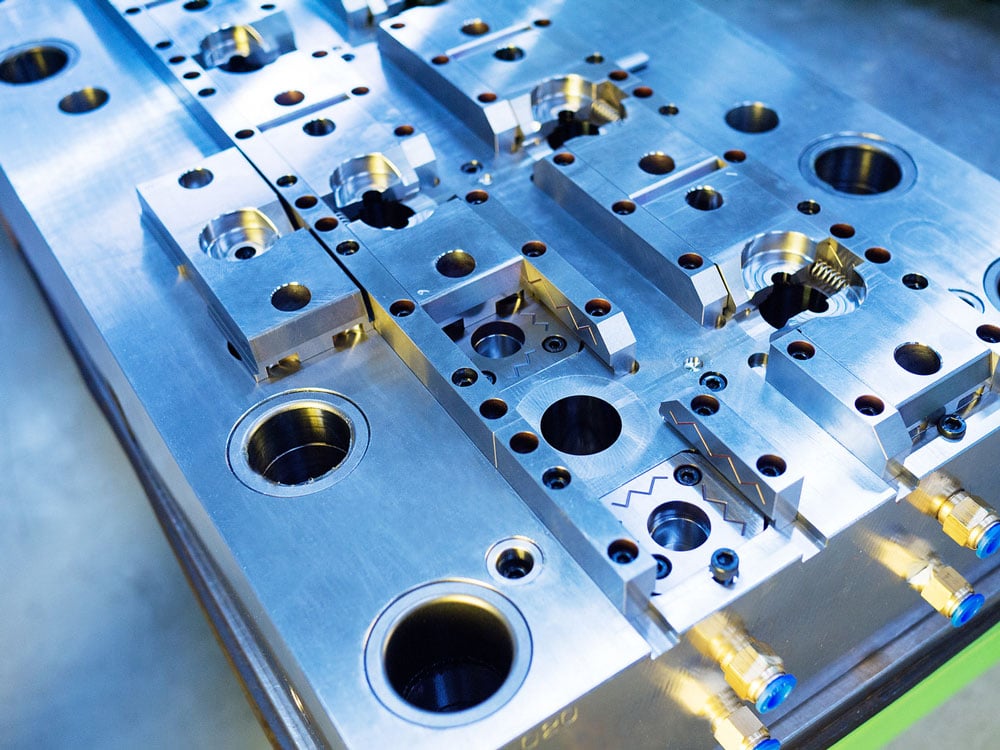

When designing custom plastic parts for injection molding, a number of characteristics must be taken into consideration. These include material properties, wall thickness, part geometry, dimension and tolerances, surface finish and texture, internal stresses and forces applied during the injection molding process, heat dissipation needs and regulations or standards that need to be complied with. Additionally, it is important to assess potential wear and tear as well as look for any potential design flaws in order to ensure the part meets all of its performance requirements.