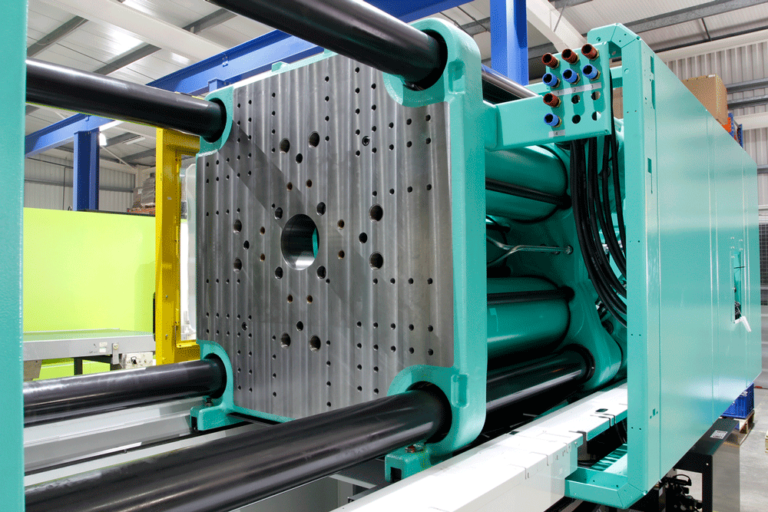

Complex Molding Techniques For Complex Parts

Injection molding is perhaps the most versatile process for creating custom plastic parts. By utilizing the complex molds involved in this process, manufacturers can create

Custom injection molding is one of the most versatile processes for creating plastic parts. From designing to producing, there are many decisions that play into the manufacturing process; one of those being short-run production vs. long-run production.

So, how do you know if short-run production vs. long-run production is best for your part?

Short-run molding typically falls into two categories.

Pioneer Plastics specializes in all of the above and is here to guide and talk you through these options and pricing so that you can make good educated decisions based on the known facts.

Long run molding – High volume production molding is achieved with multi-cavity steel molds. These molds will run anywhere from 20,000 to millions of parts per year. Upfront tooling cost will be higher because they are bigger multi-cavity molds, but they drive down part/unit cost due to pieces per hour, less time to produce and less labor. Payback on tooling cost is achieved through volume and our goal is to help our customers get that payback as soon as possible.

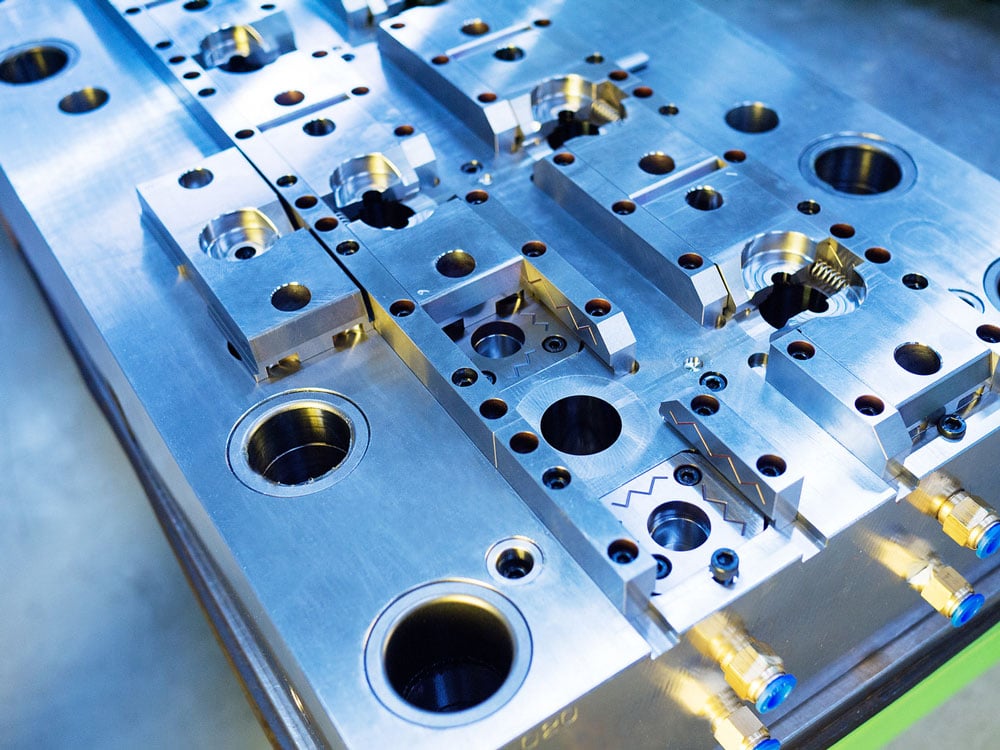

If your part is small or large complex designs may sometimes require more advanced mold techniques, meaning cams or lifts to produce this part. This will take more time and labor and will lead to an increase in mold cost.

If the part requires additional services or post operations like decorating ultrasonic welding or assembly, it will increase production time and cost. Labeling, over-molding, and heat staking are examples of additional services that your part may require to achieve your finished goods.

Get Started

Pioneer Plastics will educate you on all available options so that you know exactly what to expect at every step of the process. To get started on custom injection molding services, contact us today.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Injection molding is perhaps the most versatile process for creating custom plastic parts. By utilizing the complex molds involved in this process, manufacturers can create

Want to bring your custom injection molding back to the United States? Read on to learn more about reshoring your supply chain back to the US.

Finding the perfect display box for your collectibles is essential for preserving, protecting, and showcasing your treasured items. Whether you are a casual collector or