8 Top Benefits of Custom Injection Molding

Plastic injection molding is a custom option for manufacturing parts, and can be much more versatile than other types of plastic molding. This more efficient

The custom injection molding process starts with a conceptualized design and ends with a uniquely manufactured product.

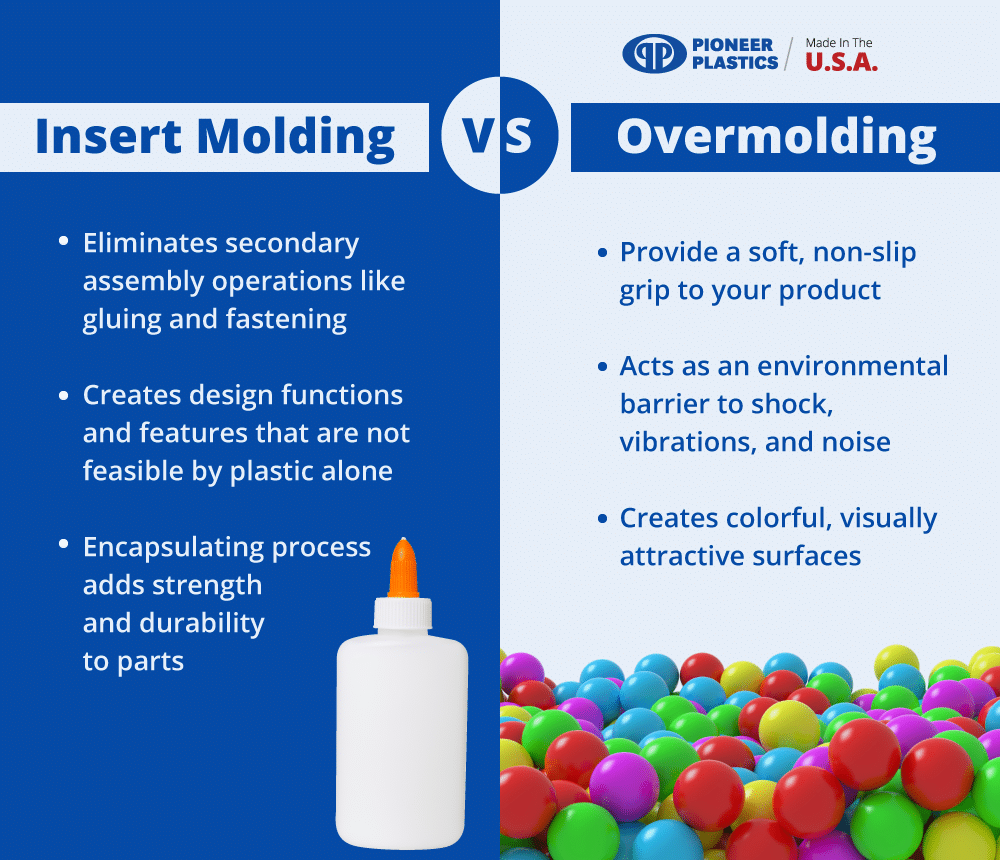

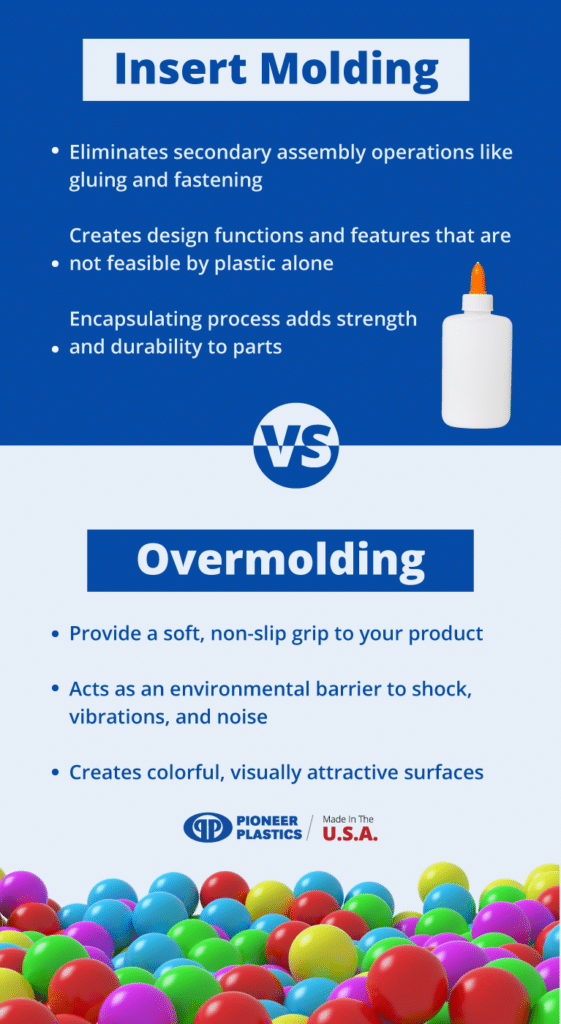

If your product needs to be aesthetically pleasing or ergonomically friendly, injection molding techniques like insert molding or overmolding might be used to achieve those needs.

It might be difficult to figure out which process is best for your custom plastic part. Here’s a break down of the insert molding and overmolding processes.

Insert molding is a process where a rigid plastic resin is injected over another material, typically metal. The metal piece is placed in a tool for the plastic to be injected around. Encapsulating the insert with plastic creates a single molded piece that’s typically stronger than one created by assembling separate pieces together.

This process is most commonly used for custom-machined metal parts like threaded fasteners and electrical parts. There is no chemical bonding between metal inserts and plastic, so the insert and resin components must be designed for mechanical bonding.

Insert molding is controllable and allows better encapsulation than other methods used to mold plastic around metal parts. Molded inserts eliminate the need for a secondary insert installation process, making it more time-and-cost-efficient.

Benefits of Insert Molding:

Overmolding is the process of adding an additional layer of resin to the existing plastic part. This process adds characteristics that a single piece of plastic can’t provide.

One common reason to use this technique is to add a soft, functional, ergonomic layer of rubber-like material (typically a thermoplastic elastomer) over a hard surface. This improves the grip of a hand-held item.

One example of this is toothbrushes. Toothbrushes are often made from a hard plastic center with a soft plastic grip around the handle.

Another use for over-molding is to change or enhance the appearance of a part by overmolding material of a different color or finish.

Thousands of possible combinations exist for over-molded material. Resins have to be adhesive and compatible with each other in order for the process to work.

If the goal of using overmolding is to enhance grip or increase cushioning in your product, make sure your injection molding company knows those goals. Factors like cushioning, flexibility, and friction will play into the type of resins that are used in the product.

Benefits of Overmolding:

We specialize in all aspects of the process- from concept to consumer. We can design, build, produce, and distribute your part. From insert molding to overmolding and so much more, we can help you produce your custom plastic part.

Contact us today to get a quote for the production of your part.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Plastic injection molding is a custom option for manufacturing parts, and can be much more versatile than other types of plastic molding. This more efficient

Reshoring manufacturing—moving production back to the United States—has emerged as a crucial strategy for reducing operational vulnerabilities, enhancing product quality, and meeting the demand for

No matter what scenario—there are several optimal and safe ways to display an autographed baseball.