Tips on Choosing The Best Diecast and Hot Wheels Display Cases

Collecting Hot Wheels™ and other diecast cars is a pastime that many of us pick up in childhood. As a child, you mainly want to

Temperature plays a huge role in the custom injection molding process– even helping to determine the type of resin the part is made from.

Resins that are specifically made for high temperatures contain properties that set them apart from other resins, making them ideal for parts that need to withstand extreme heat.

Most plastics used in the market are only suitable for use at temperatures below 275°F. Resins that are resistant to high heat can withstand temperatures ranging from 275°F to 500°F without losing its shape and/or properties.

Plastics that are resistant to high temperatures are a light, versatile alternative to metal, ceramics, and older-generation polymers.

Thermoplastics are most commonly used in consumer products (like milk jugs) that won’t need to withstand very high temperatures. Thermoplastics are also great for prototyping because the material can be reused for another prototype or for final production. Thermosets are most commonly used for parts that need to withstand extremely high temperatures.

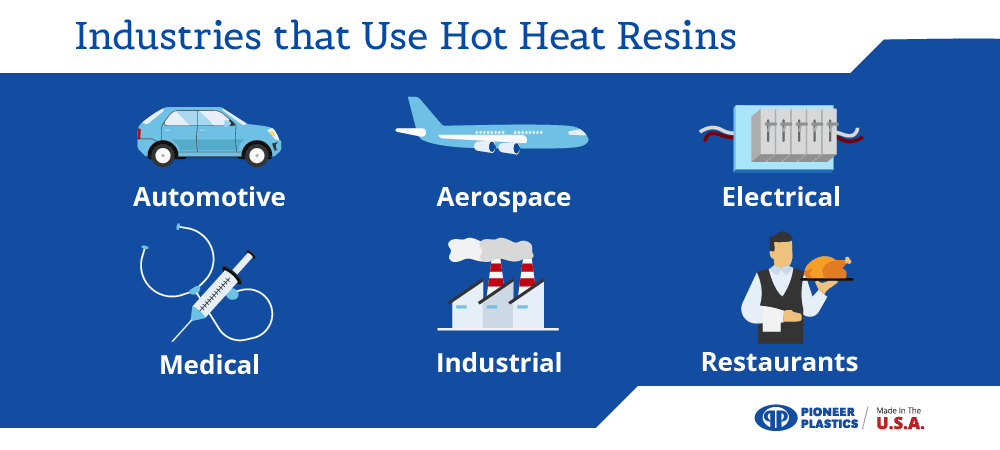

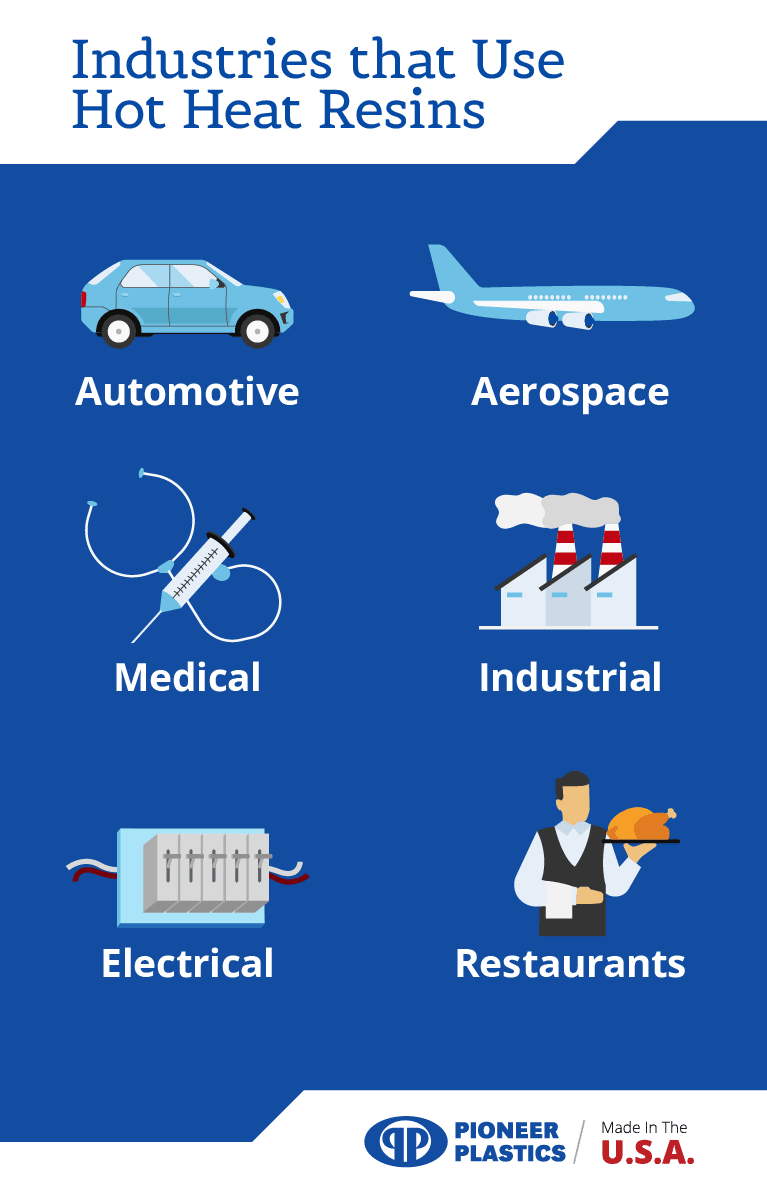

Examples of industries that use high heat resins in their products are:

Custom Injection molding with high heat resins are atypical to conventional molding. From mold design to processing, each process is different for thermoplastics and thermosets.

The mold needs to be designed for extremely high heat temperatures and clearances. They also require a special mold-temperature control unit with oil to attain adequate high mold temperatures. An experienced mold processor should handle high heat resins to ensure that the process is completed without any defects.

Pioneer Plastics has the equipment and experience to meet the heat resistance needs of your part.

If you have an idea for a custom plastic part, we can assist you every step of the way – from design to distribution. Contact us here to get a quote for custom injection molding services.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Collecting Hot Wheels™ and other diecast cars is a pastime that many of us pick up in childhood. As a child, you mainly want to

In the world of manufacturing, efficiency, cost-effectiveness, and quality are key. This is where hot runner systems in injection molding come into play, revolutionizing the

As the demand for higher-performing plastics mounts, advanced features that enhance product usability and aesthetics are becoming more common. However, integrating undercuts, thin walls, living