When Designing Custom Plastic Parts, Fit And Function are Important

When designing your custom plastic part, it’s crucial to consider what the part’s fit and function will be. First and foremost, the function of the

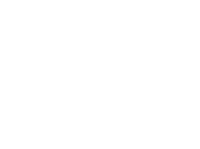

Plastic injection molding is a popular manufacturing method used to produce a wide variety of products across industries. From consumer goods to industrial components, the versatility and cost-effectiveness of plastic injection molding makes it an ideal choice for many manufacturers. However, choosing the right plastic injection molding partner can be challenging.

Partnering with the right manufacturer can mean the difference between a successful product launch and costly delays. A reliable partner must have expertise in design, material selection, and production scalability to meet your project’s unique requirements. This blog post explores key factors to consider when choosing a plastic injection molding partner and how partnering with a Made-in-USA manufacturer can offer strategic advantages.

Plastic injection molding is a versatile manufacturing process used to produce accurate and consistent plastic components. The process typically involves three main elements:

A knowledgeable plastic injection molding partner will guide you through each of these stages, ensuring that design, material selection, and scalability suit your project’s requirements.

Experience is a key indicator of reliability in plastic injection molding. A partner with years of industry experience brings a wealth of knowledge that can have a direct impact on your project’s success. Consider these benefits of working with an experienced partner:

The insights and expertise of experienced manufacturers can streamline your product development process and ensure that your project stays within budget and timeline expectations.

Every product has unique design and functionality requirements. A reliable plastic injection molding partner must be able to handle customization, turning your distinct concepts into functional, market-ready products. Key attributes of strong customization include:

These customization capabilities not only allow for innovative product designs but also offer flexibility in addressing cost, performance, and production volume requirements.

Quality is the foundation of successful plastic manufacturing. Every part must adhere to strict tolerances and performance criteria, making quality control a non-negotiable aspect of the injection molding process. Look for partners that demonstrate the following quality practices:

By maintaining high-quality standards, a manufacturing partner not only protects your investment but also builds a reliable product portfolio that satisfies customer expectations.

In today’s competitive market, speed to market is critical. An injection molding partner offering rapid prototyping and flexible production methods can significantly accelerate product development and market introduction. Key benefits include:

With a partner that prioritizes flexibility and speed, you can respond quickly to market changes, test new ideas, and achieve faster growth.

Choosing a U.S.-based plastic injection molding partner offers several strategic benefits:

Domestic manufacturing also contributes to a more resilient supply chain, reducing risks associated with international logistics and regulatory uncertainties.

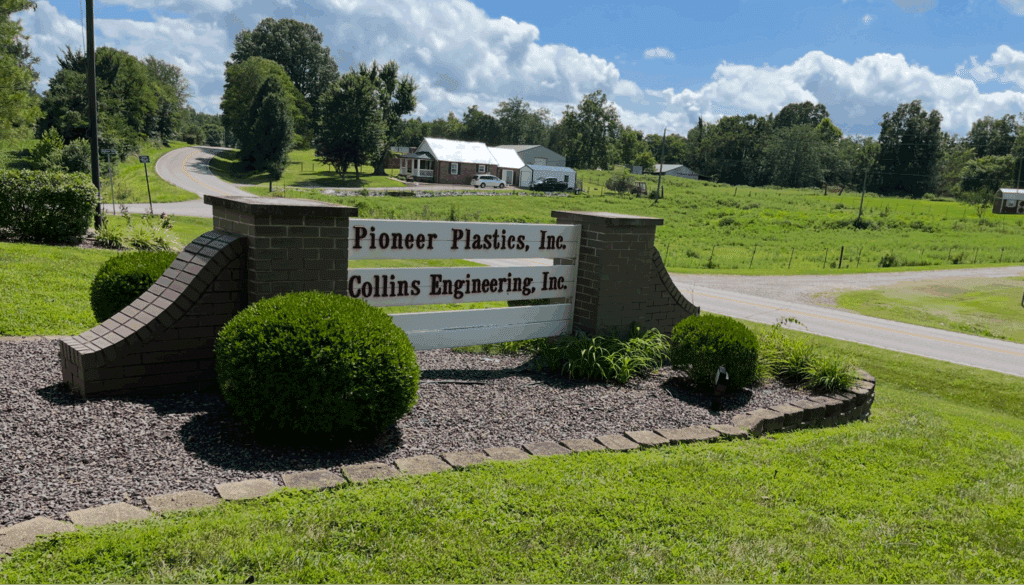

Pioneer Plastics, based in Dixon, Kentucky, exemplifies the qualities of an exceptional plastic injection molding partner. With decades of experience, they have a proven track record of delivering innovative, high-quality solutions tailored to diverse industries, from food service to appliances.

Their collaborative approach ensures seamless communication and iterative design processes, as demonstrated in their work with a global pizza chain. By leveraging advanced technologies like 3D printing and in-house tool building, they developed a groundbreaking device that slashed operational costs and earned them the prestigious Supplier of the Year award. This commitment to innovation, quality, and customer satisfaction makes Pioneer Plastics a trusted partner for transforming concepts into reality.

To learn more about their capabilities, read the full case study on how Pioneer Plastics revolutionized a global pizza chain’s operations here.

Choosing the right plastic injection molding partner is critical to the success of your product and business. By focusing on key factors such as process fundamentals, extensive industry experience, customization capabilities, stringent quality controls, and rapid production methods, you can ensure that your manufacturing process is both efficient and reliable. Opting for a Made-in-USA partner further enhances these benefits by offering faster lead times, higher regulatory standards, and stronger communication channels.

If you are looking for a partner with decades of expertise and a proven track record in transforming concepts into high-performance, market-ready solutions, consider Pioneer Plastics. Their commitment to quality, rapid prototyping, and seamless collaboration means they are well-equipped to bring your ideas to life with precision and excellence. Contact Pioneer Plastics today to learn more about their custom injection molding solutions and see how they can meet your production goals.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

When designing your custom plastic part, it’s crucial to consider what the part’s fit and function will be. First and foremost, the function of the

DIXON, Kentucky – Pioneer Plastics was selected as Pizza Hut’s STAR Award recipient for Equipment and Smallwares Supplier of the Year for 2020. This marks

Plastic injection molding is a custom option for manufacturing parts, and can be much more versatile than other types of plastic molding. This more efficient