5 Tips for Displaying and Protecting Your Autographed Baseball

No matter what scenario—there are several optimal and safe ways to display an autographed baseball.

In today’s dynamic manufacturing world, finding a production method that is both efficient and adaptable is crucial for meeting unique customer demands. Custom injection molding excels in delivering precision-crafted plastic components across a wide range of industries. This process enables the creation of highly specific products, from durable industrial parts to sleek display cases for collectibles, making it a cornerstone of modern manufacturing.

Leading the charge in this field is Pioneer Plastics, a respected injection molding partner with over 60 years of experience. Based in Dixon, KY, Pioneer Plastics specializes in transforming innovative concepts into high-quality, customer-ready products. Their commitment to maintaining strong manufacturing standards alongside their versatile and detail-oriented approach makes them a reliable solution provider for a diverse array of custom plastic needs.

Injection molding is a highly efficient manufacturing process that involves injecting molten plastic into a specifically designed mold, where it cools and solidifies into the final product. Known for its precision and reliability, injection molding is ideal for creating complex shapes with tight tolerances, making it an indispensable method in modern production.

This process has revolutionized industries by enabling the mass production of diverse plastic components. Its adaptability to a wide range of materials, including standard plastics and advanced engineering-grade resins, ensures it can fulfill the unique demands of virtually any application. Whether producing small, detailed pieces or larger, durable structures, the injection molding process provides the scalability and consistency required for efficient manufacturing.

By combining versatility and precision, injection molding has become a cornerstone technology for industries ranging from food packaging to collectibles, demonstrating its significant value in today’s manufacturing landscape.

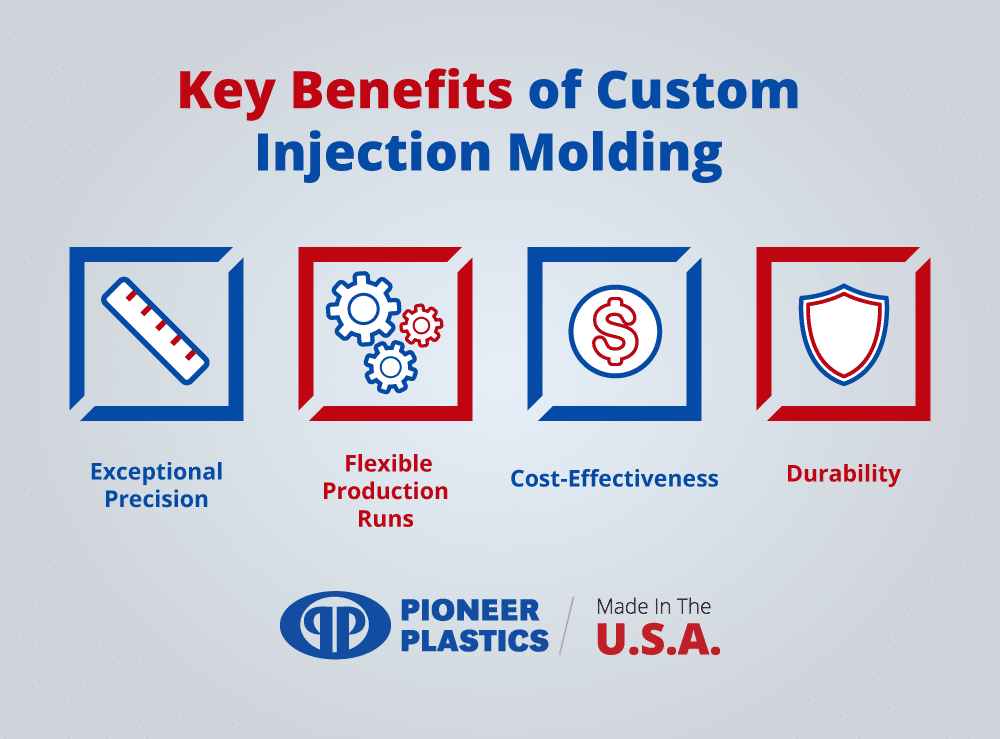

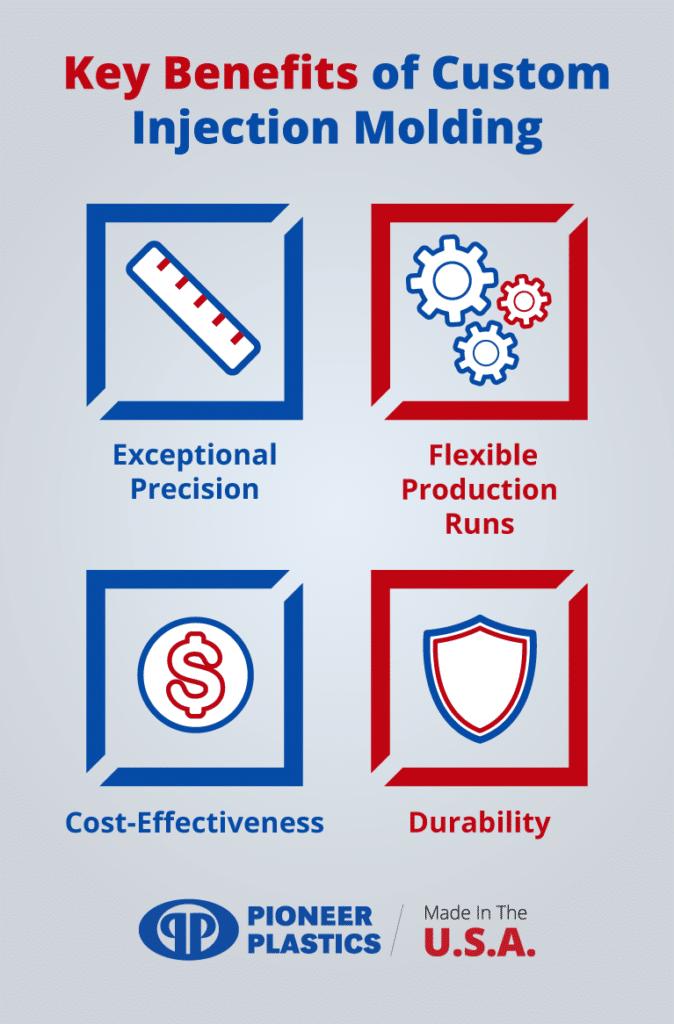

Custom injection molding offers a multitude of advantages that make it one of the most reliable manufacturing methods for producing high-quality plastic components. From precision to cost-effectiveness, here’s how this process stands out:

Injection molding is renowned for its ability to produce parts with unparalleled precision. This process ensures that every item adheres to exact specifications, providing uniformity across production runs. For industries where intricate designs and tight tolerances are essential, such as in medical devices or automotive components, injection molding delivers the consistency required to meet demanding quality standards.

Custom injection molding is a highly adaptable solution. It can accommodate short-run production for niche markets while also scaling efficiently for long-term, high-volume manufacturing. Pioneer Plastics supports businesses of various sizes and production needs, aiming to provide fast turnarounds without compromising quality.

By injecting precise amounts of material into molds, injection molding minimizes waste during production. This material efficiency, combined with high-speed production cycles, helps reduce overall manufacturing costs. Furthermore, the streamlined process supports sustainable practices by conserving resources and lowering energy usage. For businesses looking to enhance profitability without sacrificing environmental responsibilities, injection molding presents an advantageous choice.

Products made through injection molding benefit from the strength and resilience of engineering-grade plastics. These materials not only meet demanding performance requirements but also ensure durability for long-term use. Pioneer Plastics specializes in using premium plastics that provide excellent durability, chemical resistance, and mechanical strength, helping clients achieve long-lasting, reliable products ideal for even the toughest applications.

While injection molding offers many advantages, it does come with some challenges. For instance, the cost of creating custom molds can be high, which may deter smaller-scale projects. Design constraints within the process may also limit complex shapes in some cases. By working with an experienced company like Pioneer Plastics, these challenges can be mitigated through expert guidance and efficient planning.

Custom injection molding is more than just a method for creating plastic parts—it’s an adaptable, cost-efficient, and high-performing solution that meets the unique needs of various industries and projects.

The flexibility of custom injection molding shines through its extensive applications across a wide range of industries. Pioneer Plastics leverages this adaptability to develop tailored solutions that align with the specific needs of their clients, whether they are businesses or manufacturers.

For collectors, safeguarding cherished items while showcasing them in an eye-catching way is paramount. Pioneer Plastics caters to this audience with precision-manufactured diecast and collectible display cases. Designed for sports memorabilia, toys, and models, these cases enhance the visual appeal of collectibles while providing durable protection against dust and damage. The use of custom injection molding allows each display case to be tailored to specific dimensions and aesthetic preferences, blending practicality with presentation.

The food industry demands packaging solutions that prioritize safety, durability, and visual appeal. Pioneer Plastics delivers with their clear plastic containers, created to meet rigorous food safety standards. Ideal for storing, packaging, and displaying food products, these containers combine practicality with an appealing aesthetic. The clear, sturdy plastic provides excellent visibility for consumers while maintaining the integrity of food items during transport, storage, or retail display.

Injection molding is a crucial process in the production of appliances, enabling the creation of durable parts with precise detailing. Pioneer Plastics is a trusted supplier to the appliance industry, providing custom injection molding for diverse components such as refrigerator shelves, dishwasher racks, and oven knobs. With their expertise and state-of-the-art equipment, Pioneer Plastics helps manufacturers meet the high standards of functionality and aesthetics required by the appliance industry.

For companies requiring specialized components that cannot be sourced off-the-shelf, Pioneer Plastics provides custom plastic parts crafted to meet precise specifications. These tailored solutions highlight the company’s expertise in addressing complex challenges with precision and quality.

By delivering carefully designed display cases, food-safe containers, innovative household products, and bespoke plastic parts, Pioneer Plastics showcases their versatility and dedication to turning ideas into functional, high-quality solutions.

With over three decades of experience in the injection molding industry, Pioneer Plastics has established itself as a trusted partner for businesses and manufacturers seeking high-quality plastic products. The journey from concept to finished product can be complex, but Pioneer Plastics simplifies the process by guiding clients every step of the way. Their team of experienced engineers and technicians collaborates closely with customers to understand their unique vision and specifications.

Pioneer Plastics stands out in the custom injection molding industry by offering a blend of extensive experience, technical expertise, and a commitment to quality. Whether you are in need of precision-crafted parts, durable storage solutions, or innovative household items, contact Pioneer Plastics today to bring your ideas to life with excellence and reliability.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

No matter what scenario—there are several optimal and safe ways to display an autographed baseball.

You’ve worked hard, maybe for years, to invent a plastic product that will either increase efficiency or improve the user experience in some way. So

When designing your custom plastic part, it’s crucial to consider what the part’s fit and function will be. First and foremost, the function of the