10 Household Products Powered by Injection Molding

Injection molding has drastically changed the way everyday items are produced. The process involves melting plastic pellets and injecting them into custom molds to create

367 million metric tons of plastic were produced in 2020 — a million metric tons less than the record high of 2019. From bottles and toys to automotive parts and surgical supplies, the unique material properties of plastic have given it an important place in our everyday lives.

But how do plastic parts factories manufacture plastic parts, and which method best suits your project?

Although the compounds and molecular structure of plastics vary significantly, the techniques used to form these items are relatively simple.

By far the most versatile plastic molding process, injection molding enables the manufacturing of plastic parts with the most complex geometry. The first step in the process is to design a custom mold according to the shape of the desired finished product. This type of mold is usually made with steel, due to its high melting point and chemical stability.

Once the mold is created, it is put into an injection molding machine. Plastic granules are melted and injected into it. The molten plastic is pressed to ensure uniformity and a proper fit within the mold. Once the molten plastic has been adequately pressed into the mold, it is allowed to cool until it sets. The final product is ejected from the mold — typically by a set pins or air to blow it off — and can be finished according to spec.

There are many different types of presses available for use, and they are rated according to how much force (measured in tonnage) they can deliver. A few parameters to consider when selecting a press are: required force, material flow index (MFI), clamping requirements, and safety factor — among others.

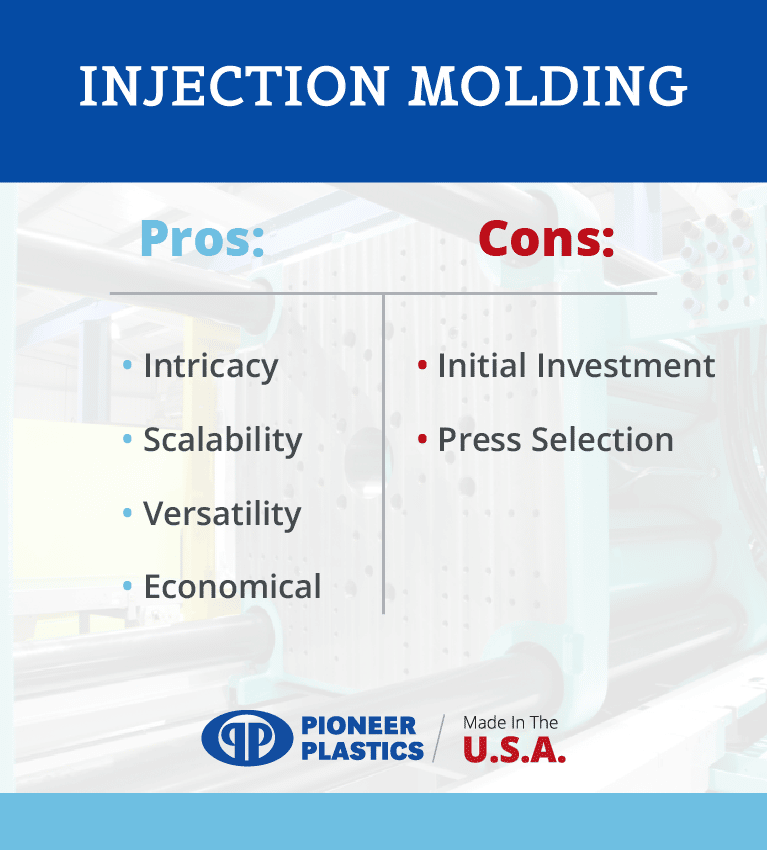

There are several advantages to injection molding over other plastic molding production methods, like:

Despite its many advantages, some drawbacks of injection molding do exist, namely:

Overall, injection molding offers comparatively few drawbacks relative to the many benefits of this highly efficient manufacturing method. No wonder it’s the most common plastic manufacturing method!

Despite all the uses of injection molding, there are some plastic parts where a different manufacturing method is required. One such scenario is when a press cannot be used to fill the molten plastic within the mold. This is often the case with large, hollow, one-piece parts, such as containers, tanks, bladders, etc.

In applications like these, rotational molding is an excellent alternative. Here the plastic pellets are injected into a mold as before, but instead of being pressed to fill the cavity, they are rotated (or shaken) to deliver an even coating within the mold. Also known as rotomolding, this production method relies on the principle of centrifugal force to distribute the plastic uniformly.

Just as press selection is a key component of injection molding, determining the proper rotational speed is crucial in rotomolding design. Typical rotational molding occurs at relatively slow rates, with average speeds ranging from 2 to 20 RPM. Too slow, and the molten plastic may not experience enough centrifugal force to be moved. Too fast, and it may not coat the mold evenly.

Other parameters to consider are operating temperature, MPI, and wall thickness.

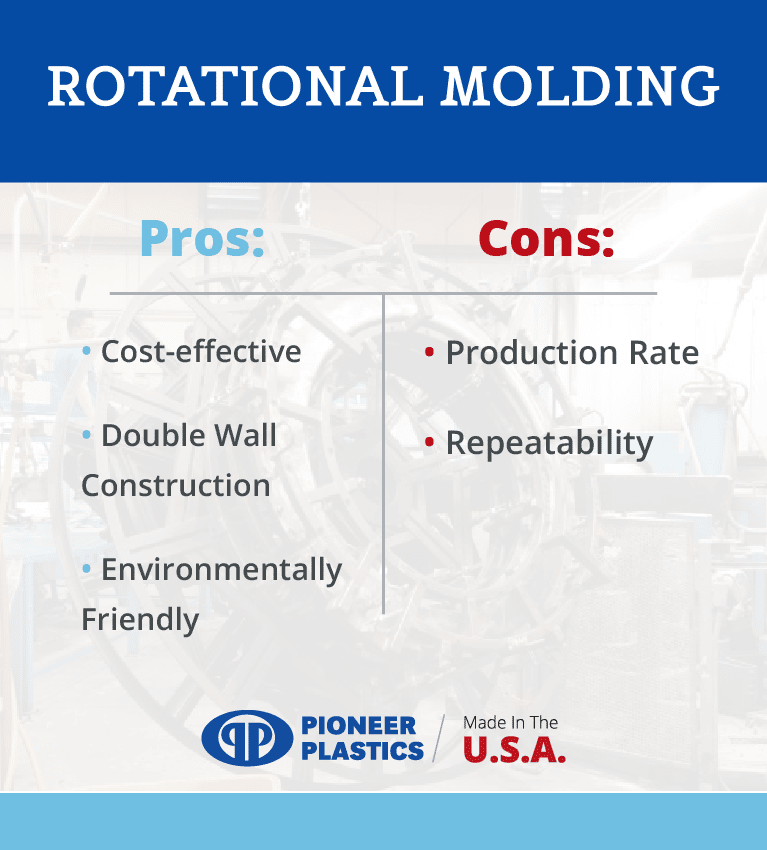

Some of the primary benefits offered by rotational molding include:

No manufacturing process is perfect, and rotomolding is not without its flaws. A few weaknesses are:

These drawbacks should be considered within the product design process, but they don’t take away from the fact that rotational molding is still a very effective way of making certain plastic parts.

Another very common manufacturing method is blow molding. Useful for manufacturing hollow parts like bottles or jugs, blow molding involves the expulsion of air into a heated plastic mass or tube until it is forced up against the walls of a mold and reaches the desired geometry. The mass or tube is known as a parison, and the entire process is very similar to blown glass production.

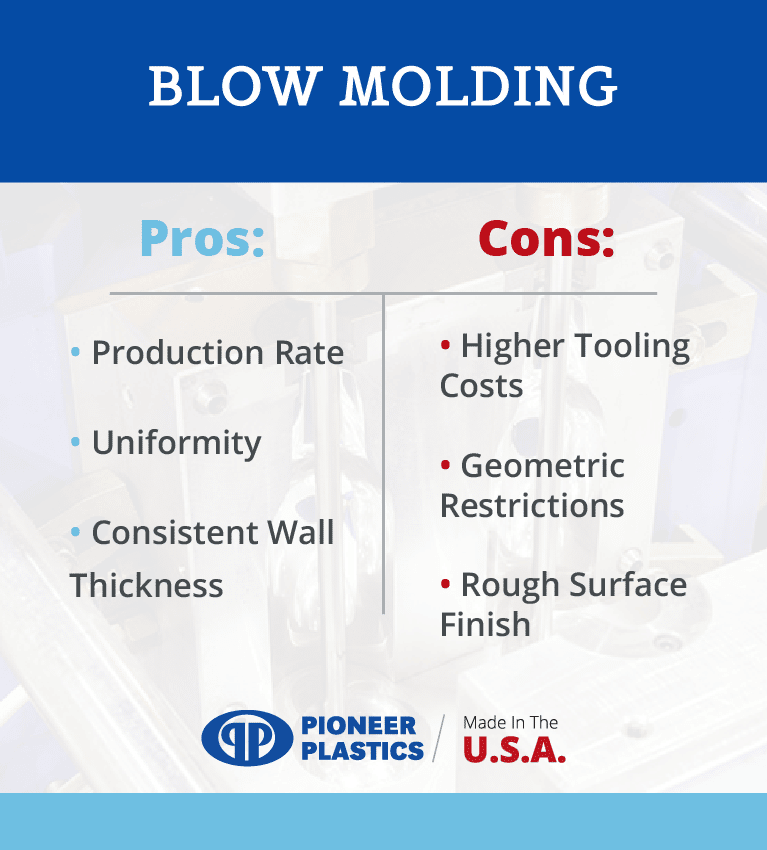

Because both are used in the making of hollow plastic parts, blow molding and rotational molding are often compared when selecting a manufacturing method. The two are very different, though, as both the method and application vary significantly. Here are the pros and cons of each:

Although an excellent choice for quickly producing uniform, thin-walled products, blow molding is not the best choice for every project. Some of the disadvantages of blow molding are:

Overall, blow molding is very suitable for the mass production of simple, inexpensive parts. However, its much higher tooling costs and rougher exteriors should be taken into account.

There are many factors to consider when selecting the manufacturing process that will make your product come to life. Injection molding is an efficient, customizable way to produce the most complex product geometries, but design parameters, like material selection, must be considered carefully.

For hollow parts where a part would fail, rotational molding allows for detailed features with minimal machining, but production rates can be slower, and the softer tools used may need to be replaced more often. Blow molding is highly effective for rapidly manufacturing simple, cost-effective designs, but the tooling costs are much higher — and still other methods like extrusion and compression molding are available.

At Pioneer Plastics, our designers and engineers have extensive experience molding plastic parts. We understand the manufacturing process, and can help you select the most efficient way to build your product. Contact us today, and we’ll turn your plastic design into a reality.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Injection molding has drastically changed the way everyday items are produced. The process involves melting plastic pellets and injecting them into custom molds to create

The choices we make as consumers have profound impacts in our interconnected global economy. Selecting American-made products isn’t just about patriotism; it’s about investing in

Whatever you collect, from books to memorabilia to antiques, protecting your collectibles should be a top priority. If you have a home full of one-of-a-kind