Injection Molding: Your Questions Answered

If you have an idea for a custom plastic part, you may have a lot of questions about the manufacturing process. Injection molding is a

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

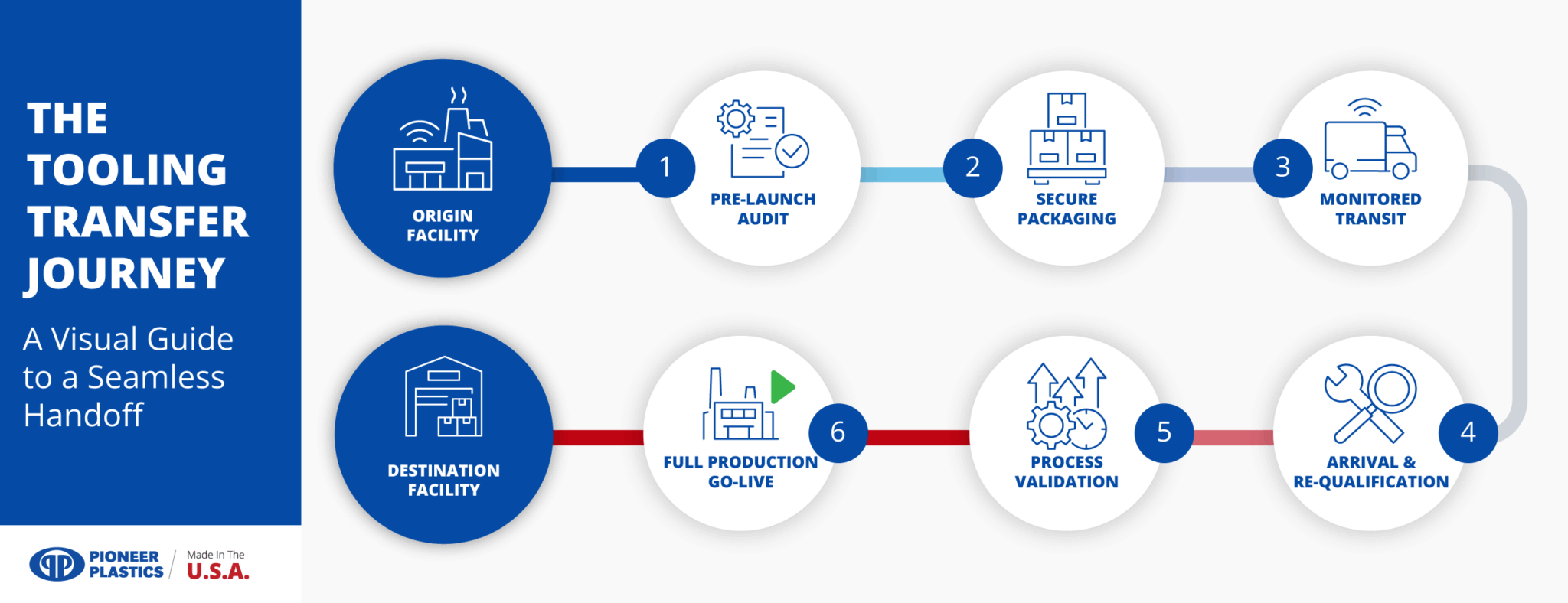

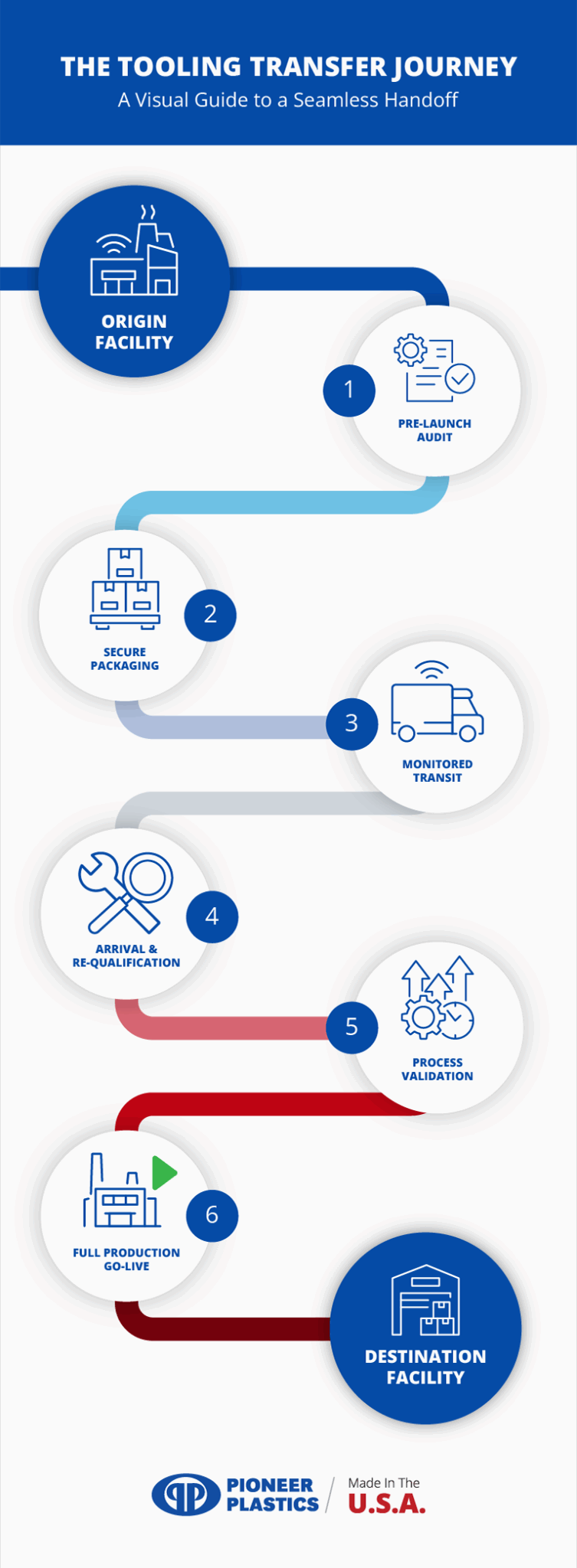

Tooling transfers involve relocating molds from one production facility to another—a critical process for Original Equipment Manufacturers (OEMs) looking to optimize supply chains, enhance quality, or reshore production. Poor planning can lead to delays, hidden costs, and quality risks.

This guide explains key factors for successful tooling transfers, outlines the true costs involved, highlights common pitfalls, and provides actionable strategies to maintain consistent quality and minimal downtime.

A successful tooling transfer is an orchestrated process built on four foundational pillars. When these are firmly in place, the transfer proceeds smoothly, protecting quality and minimizing downtime.

A phased approach reduces potential shocks to production and ensures a well-organized reintegration:

Implementing these steps sequentially allows issues to surface early, limiting their impact on production.

While understanding the core principles of a transfer is crucial, successful execution depends on two tangible tools: the Request for Quotation (RFQ) and the internal project checklist. The RFQ sets the stage for a successful partnership with your new molder, while the checklist serves as your internal roadmap to ensure no detail is overlooked.

A detailed and unambiguous RFQ is the foundation of effective vendor communication. It goes beyond simply asking for a price; it sets clear expectations for quality, timelines, and responsibilities, eliminating potential disputes before they begin. An effective RFQ should always include:

To ensure these cornerstones are addressed, a detailed checklist is your most valuable tool. While a comprehensive plan is essential, here are the absolute must-haves to get you started:

Beyond the day-to-day logistics, a successful tooling transfer hinges on three interconnected strategic decisions that will define the project’s outcome. These choices—who you partner with, where they are located, and what the true financial commitment will be—require careful evaluation to ensure the transfer achieves its intended business goals, whether they are to improve quality, reduce costs, or enhance supply chain resilience.

The single most critical factor in a tooling transfer is the capability of your new molding partner. A world-class facility can make even a complex international transfer feel seamless. Look for a partner who demonstrates excellence in these key areas:

The partner’s location introduces another layer of strategic trade-offs. The decision between a domestic and an offshore transfer often comes down to balancing cost against control and speed.

Ultimately, balancing potential cost savings with the need for reliable quality control, clear communication, and supply chain agility is essential when making your decision.

A common and costly mistake is to underestimate the transfer’s total financial impact by focusing only on the initial quote for moving the mold. The shipping fee is often just the tip of the iceberg. To create a realistic budget, you must calculate the Total Cost of Ownership (TCO) for the project, which includes several often-hidden expenses:

A comprehensive TCO analysis provides the financial clarity needed to validate your choice of partner and location, ensuring the transfer achieves its strategic goals without derailing your budget.

With over four decades of experience, Pioneer Plastics excels at managing complex tooling transfers. Our US-based manufacturing model ensures rapid prototyping and shorter lead times compared to many overseas options. From comprehensive in-house tool building services to advanced engineering services for plastics, we prioritize quality, efficiency, and IP protection. Our team integrates effective planning, dedicated communication, and careful tool management to handle each stage of your transfer enabling you to focus on product innovation rather than worrying about mold relocation and validation.

Tooling transfers in injection molding can be a complex endeavor. However, strategic planning, realistic cost assessments, clear communication, and a phased process keep production on schedule and protect quality.

Pioneer Plastics is ready to support you every step of the way. Contact us for a smoother tooling transfer process or to request a tailored quote. We look forward to helping you secure dependable, cost-effective production for all your custom injection molding needs.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

If you have an idea for a custom plastic part, you may have a lot of questions about the manufacturing process. Injection molding is a

For businesses seeking to streamline operations while managing costs, the initial appeal of cheaper plastic display cases can be strong. While lower upfront expenses may

What would summertime be without having a blast at a festival, fair, or carnival? In almost every community, summertime brings locals and visitors to outdoor