Initially, lower-cost plastic display cases might appear to meet basic requirements for sturdiness and visual appeal, offering an attractive upfront savings. However, this perception can be misleading. Manufacturers focused on reducing production costs often do so by using substandard materials or implementing inconsistent processes that introduce critical flaws into the final product.

For example, essential features like UV protection may be overlooked, leading to tangible issues such as warped lids or significant discoloration over a short period. These defects are the first sign of a larger problem, underscoring the importance of looking beyond the initial purchase price.

The Inevitable Product Flaws

These trade-offs in manufacturing quality manifest in a series of common physical failures that directly impact product integrity, presentation, and reliability. Over time, businesses often experience:

- Frequent breakage: Lower-grade plastics may crack or shatter during shipping or normal handling, resulting in a higher rate of replacements.

- Poorly fitting lids: Inconsistent production processes can lead to ill-fitting lids that compromise the level of protection.

- Discoloration: Lower-quality materials sometimes yellow or fade more quickly, reducing the professional presentation of products.

The Cascade into Operational Chaos

While elevated replacement rates are problematic, the true cost of these physical failures is the chain reaction of logistical setbacks they trigger. Reliability plays a crucial role in modern production and distribution, and cases that fail to perform consistently can undermine your entire business operation.

- Supply Chain Disruptions: If the launch of a new product line hinges on the timely arrival of durable, uniform cases, any last-minute failures can delay critical deadlines, impede future releases, and create costly bottlenecks.

- Increased Labor and Unplanned Costs: Malfunctioning cases generate unplanned procurement tasks, pulling teams away from their core responsibilities. This increases labor costs and risks further delays in product rollouts as staff are forced to react to preventable emergencies.

Beyond the Price Tag: The True Total Cost of Ownership

A comprehensive understanding of the total cost of ownership (TCO) is essential for any informed procurement decision. This framework looks far beyond an item’s initial purchase price to encompass all direct and indirect costs incurred throughout its entire life cycle. This includes not only the initial outlay but also ongoing costs related to maintenance, replacement, associated labor, and operational disruptions.

Focusing solely on upfront savings often obscures these substantial long-term expenses, turning an apparent bargain into a significant financial liability over time.

Myth-Busting: The Flaw in Cost-Driven Procurement

The common assumption that cutting costs on components like display cases automatically yields the best return on investment is a dangerous myth. This short-term approach dangerously overlooks the significant long-term implications for brand image and operational stability.

- The High Cost of Failure: Industry analyses show that unexpected supply chain disruptions, even those caused by the failure of a simple component during a large order, can directly impact shareholder value. The reliability of a display case is not a trivial detail; it is a crucial factor in maintaining a smooth-running operation.

- Brand Perception at Risk: The quality of a display case directly influences how customers and distributors perceive the product within. If a case fractures easily or presents poorly, they may lose confidence in the entire product line, leading to increased returns, reputational damage, and lost sales. In a competitive market, a single negative experience can have lasting financial repercussions.

Calculating the Hidden Expenses of Poor Quality

An inexpensive display case may appear economical on the initial invoice, but its true cost accumulates through a series of hidden operational and financial drains. Each product failure triggers a chain reaction of expenses that go far beyond the price of a replacement unit.

These hidden costs include:

- Replacement & Material Costs: The direct expense of ordering new units to replace broken or defective ones.

- Associated Labor Costs: The significant staff hours spent processing returns, managing emergency shipments, troubleshooting failures, and handling customer complaints.

- Operational Drag: The loss of overall efficiency and profitability when resources are continuously diverted to manage defective products instead of focusing on core business activities.

The Strategic ROI of Investing in Quality

Conversely, the return on investment (ROI) in quality extends far beyond simple durability, offering tangible and strategic advantages. Premium cases significantly reduce failure rates, which in turn enhances brand perception and maintains crucial customer trust.

Research shows a significant proportion of customers will avoid repurchasing from a brand after receiving damaged products, illustrating how poor-quality cases can directly erode customer loyalty.

Investing in a premium solution delivers substantial long-term economic benefits:

- Fewer Replacements: Enhanced materials and superior manufacturing dramatically reduce the likelihood of breakage, directly cutting both material replacement and associated labor costs.

- Enhanced Brand Image: A consistent, professional appearance supports the perceived value of the product, fostering repeat business and positive word-of-mouth referrals.

- Lower Disruption Risk: More reliable products minimize supply chain interruptions, helping to ensure timely and successful product launches.

While premium solutions may command a higher upfront cost, a thorough TCO evaluation that factors in reduced risk, brand equity, and long-term operational smoothness almost always reveals a more compelling and advantageous investment.

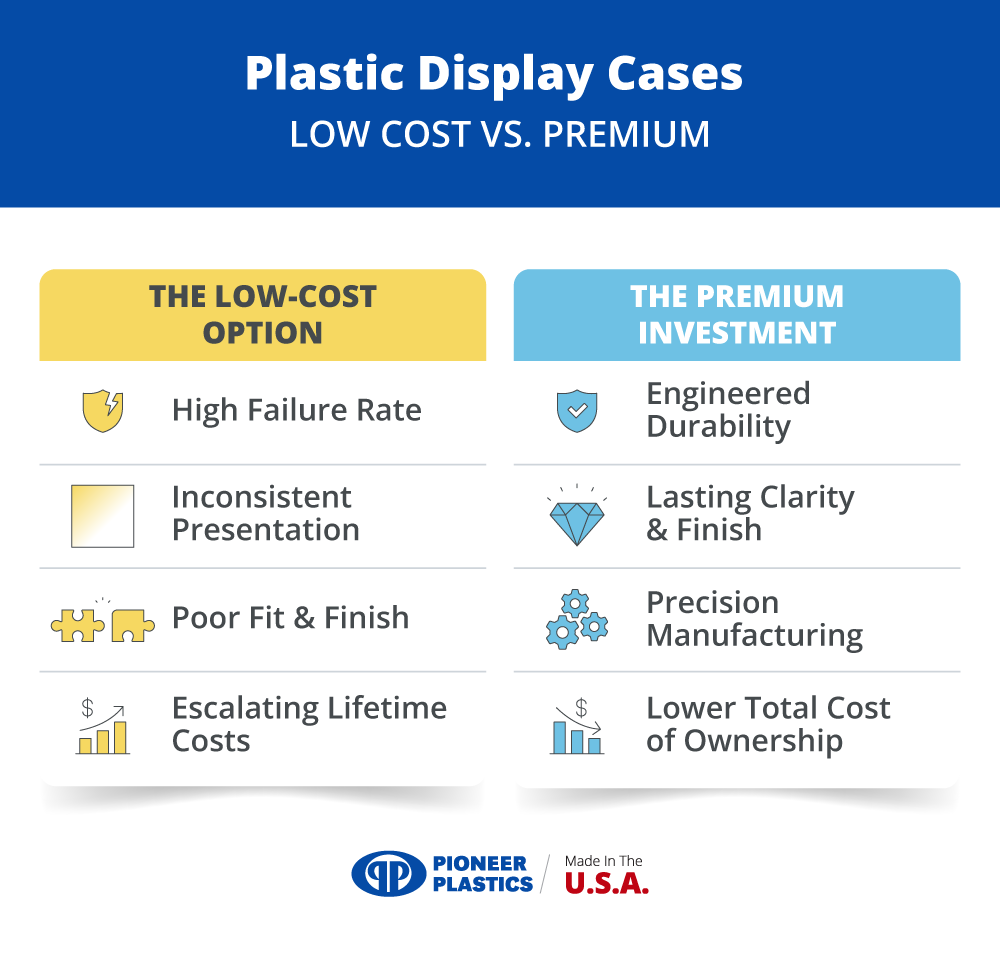

The Premium Advantage: A Cost-Benefit Comparison

Choosing between low-cost and premium cases requires looking beyond upfront savings to long-term value. While cheaper cases seem economical, they are more prone to defects over time. This leads to frequent replacements, driving up hidden labor costs and harming customer satisfaction with poor presentation from cracked or faded packaging. This cycle of failure ultimately negates any initial savings.

In contrast, premium display cases are an investment in quality materials and precise manufacturing. They are engineered for reliability, offering measurable long-term value.

Key benefits of investing in premium quality include:

- Superior Durability: Made with better materials and controlled processes, premium cases resist cracking and wear. This means lower defect rates, less downtime, and a longer service life.

- Consistent Appearance: Specialized materials maintain clarity and resist yellowing, ensuring a professional look that protects brand integrity.

- Precision Engineering: Strict quality control results in precise dimensions and secure, well-fitting lids, ensuring reliable protection and eliminating common defects.

Lower Lifetime Costs: Though the initial investment is higher, premium cases save money over time. Their long lifespan and reliability eliminate the recurring replacement, labor, and shipping costs associated with cheaper alternatives.