Advantages of Custom Injection Molding

Custom injection molding is one of the most versatile processes for creating a custom plastic part. There are many benefits to the process of custom

Pioneer Plastics, located in Dixon, KY, is a renowned figure in the custom injection molding industry, known for delivering high-quality solutions tailored to meet diverse industry needs. With a commitment to precision and innovation, Pioneer Plastics has established itself as a significant player in the manufacturing sector, offering extensive services that range from product design consultation to producing finished components. In this case study, we delve into a successful partnership with a national building supply manufacturer, showcasing Pioneer Plastics’ expertise and dedication.

Pioneer Plastics offers a wide array of products and services customized to client needs across various industries, including automotive, consumer goods, and industrial applications. Noteworthy offerings include product design and development, prototype maturation, and final production rollout. The company’s competitive edge lies in its ability to integrate advanced computer-aided design (CAD) tools with traditional molding expertise, ensuring that each product is not only functional but also optimized for cost and manufacturability.

Pioneer Plastics holds a prestigious position in the injection molding sector, bolstered by a reputation for reliability and ingenuity. Known among its customers and peers for its customer-centric approach and ability to tackle complex projects, the company has carved out a niche that values innovation and quality assurance. Testimonials from long-term clients reflect high satisfaction levels and Pioneer Plastics’ ability to cultivate lasting partnerships by acting as a true extension of their teams.

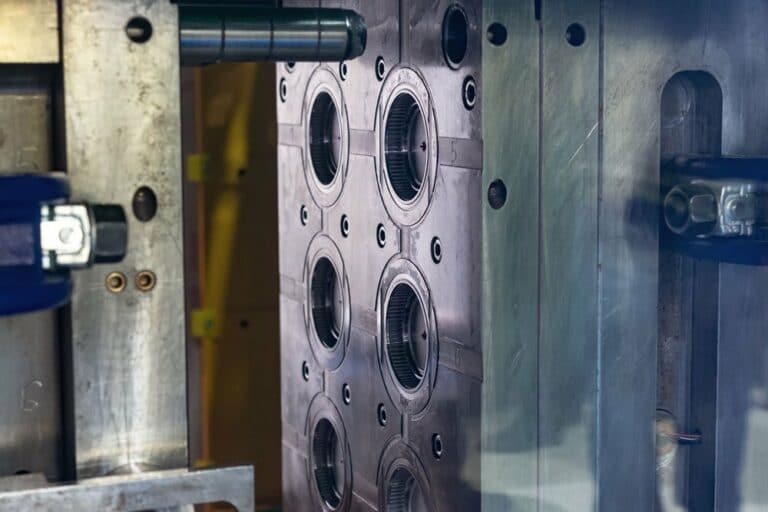

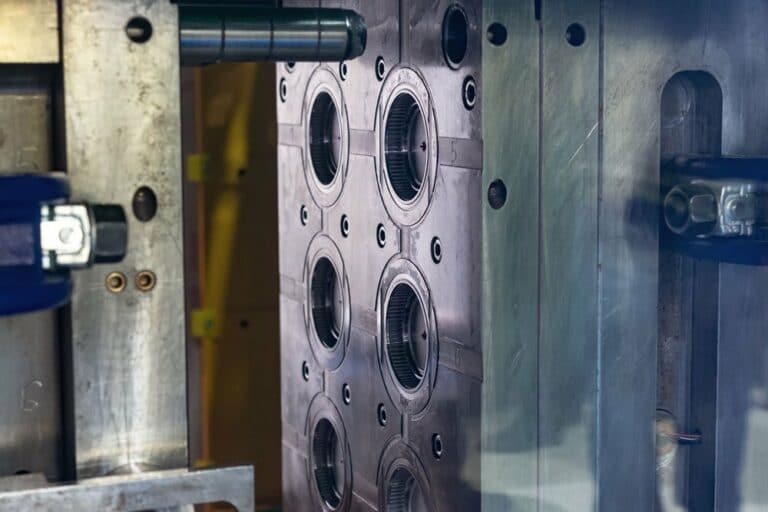

A national building supply manufacturer approached Pioneer Plastics with a near-final product design, seeking expertise in material selection and mold creation. While the design itself was nearly complete, the client was keen on input regarding the best materials suitable for their application, which had to meet stringent durability and environmental criteria.

Pioneer Plastics initiated a consultative process to review the design, assessing potential materials that would enhance longevity and user satisfaction. After detailed discussions, a specialized polymer material was selected. Once the material choice was settled, Pioneer Plastics engineered and built a precise mold that captured the design specifics, while allowing for subtle improvements to ensure the product’s fit and functionality.

Throughout the developmental phase, Pioneer worked closely with the manufacturer, making iterative adjustments to the mold to fine-tune its performance. The successful execution of this project not only met the manufacturer’s expectations but also improved the end-user experience significantly, translating into higher satisfaction and repeat business for the client.

The collaboration with the national building supply manufacturer underscores Pioneer Plastics’ capability to not only meet but exceed client expectations through expert consultation and precise execution. This case is a testament to the company’s strategic approach in aligning technological solutions with client needs, ensuring optimal outcomes. Looking to the future, Pioneer Plastics remains poised to leverage its expertise and robust industry reputation to venture into new markets, continuing to offer innovative molding solutions that address evolving industrial challenges. The company’s trajectory suggests a promising outlook, fueled by a commitment to quality, customer satisfaction, and technological advancement.

Custom injection molding is one of the most versatile processes for creating a custom plastic part. There are many benefits to the process of custom

In the world of mass production, efficiency, cost-effectiveness, and quality are non-negotiable factors. This is precisely why injection molding has emerged as a preferred choice

DIXON, Kentucky – Pioneer Plastics has been named Pizza Hut’s STAR Award recipient for Overall Supplier of the Year, as well as Equipment/Smallwares Supplier of