Understanding Essential Plastic Molding Machine Components

Plastic molding machines are integral to modern manufacturing, converting raw plastic into finished products using a combination of heat, pressure, and motion. They facilitate the

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

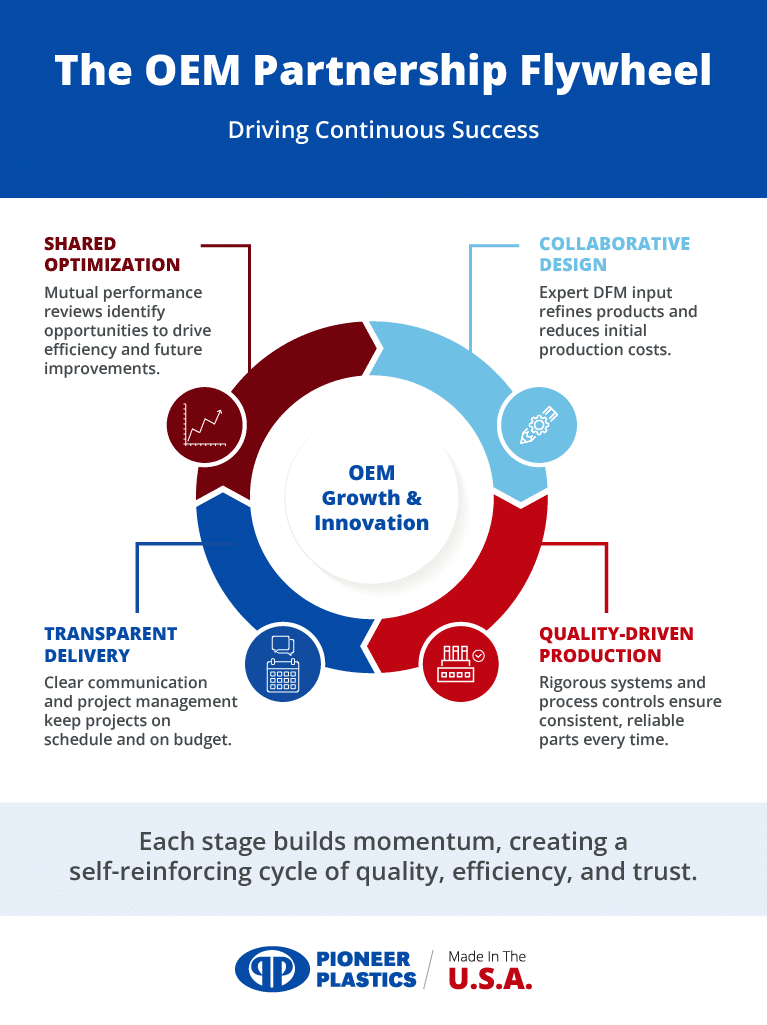

In today’s competitive environment, Original Equipment Manufacturers (OEMs) face intense pressure to deliver innovative products while controlling costs and timelines. For OEMs relying on plastic components, choosing the right injection molding partner can significantly impact every stage of the product lifecycle—from speeding up production to ensuring design precision and protecting intellectual property.

This article outlines the key elements of a successful OEM injection molding partnership and explains how working with experienced, U.S.-based suppliers can help overcome challenges and drive long-term efficiency. Whether you’re reassessing your current supplier or exploring new options, the insights below will enable you to select the right partner and build a collaboration that delivers consistent and improved outcomes.

Finding the right injection molding partner is more than a transactional relationship—it is about building a long-term collaboration that consistently delivers quality, efficiency, and reliability. A strong partnership addresses critical challenges:

Viewing suppliers as an extension of your team promotes open communication, aligned goals, and collaborative problem-solving.

Selecting the right plastics supplier is one of the most critical decisions an OEM can make. A true partnership goes beyond simple price negotiations by emphasizing shared success through collaboration, transparency, and aligned objectives. Evaluating potential suppliers requires careful consideration of factors that influence every stage of your product development, from initial design to final delivery.

An experienced supplier demonstrates deep industry knowledge and a strong track record of success. This expertise translates into higher quality parts and more efficient processes. Look for a partner who has years of hands-on injection molding experience and understands a wide range of resins, materials, and advanced manufacturing techniques. They should be able to confidently manage production scales from small prototype runs to large, high-volume orders.

Top-tier partners actively invest in your goals from the very beginning. Suppliers with robust design-for-manufacturability (DFM) services can greatly enhance your project’s viability by collaborating on prototypes, iterating designs effectively, and offering actionable feedback to refine concepts. Their insights on simplifying geometry or suggesting material modifications can lead to significant cost savings and expedited production timelines.

What to Watch Out For: A lack of collaborative spirit. A supplier who simply takes orders without offering feedback may not be invested in your long-term success. True partners work to enhance your design, not just execute it.

Quality is paramount, as the parts a supplier produces directly reflect on your brand’s reputation. Trustworthy suppliers implement rigorous quality management systems, including regular inspections and testing protocols with every production run. They utilize advanced tooling and manufacturing technologies and maintain strict adherence to industry certifications such as the ISO 9001:2015 standard, ensuring that every component consistently meets demanding specifications.

Effective project management and clear communication are the bedrock of a successful partnership. Prioritize suppliers who maintain open communication channels, provide consistent progress updates, and employ well-defined processes to identify and resolve issues promptly. A strong partner will collaborate on production schedules and set clear expectations from the start. This alignment is essential, as shared objectives in product quality, timely delivery, and cost efficiency create a focused environment that spurs measurable success.

What to Watch Out For: Communication gaps and misaligned expectations. These are common pitfalls that can cause significant delays and misunderstandings. Ensure a potential partner is willing to establish regular check-ins and designated points of contact to keep both parties synchronized.

Financial clarity is essential for effective budgeting and trust. A reliable supplier will offer detailed and transparent pricing structures that cover tooling, per-part costs, material fees, and any other potential charges. They should be willing to discuss potential cost fluctuations openly and provide predictable billing.

What to Watch Out For: Hidden costs. Prevent surprises by requesting a comprehensive cost breakdown upfront. A supplier who is not forthcoming with all potential fees may not be a trustworthy long-term partner.

Your proprietary designs are a critical competitive advantage. It is vital to partner only with suppliers who emphasize confidentiality and have robust systems in place to protect your intellectual property, in compliance with USPTO guidelines.

What to Watch Out For: A casual approach to IP. Do not work with any supplier who is unwilling to enter into protective agreements like a Non-Disclosure Agreement (NDA). Your IP is too valuable to risk.

In today’s market, a U.S.-based partner offers tangible advantages. Domestic production helps by reducing shipping distances, which can lower lead times and increase supply chain predictability. It also enhances coordination through faster, real-time communication and supports reshoring initiatives that strengthen local manufacturing operations.

Your production needs will evolve, and your supplier should be capable of adapting to both current and future demands. Key capabilities include supporting both short-run prototyping and mass production, quickly adjusting to shifts in project timelines or production volumes, and managing inventory and project schedules efficiently.

What to Watch Out For: Inadequate change management. A partner without robust change control processes may struggle to handle design or volume modifications smoothly, potentially compromising quality and timelines.

Developing a strong OEM-supplier relationship requires ongoing collaboration and a commitment to continual improvement.

Trust is the foundation of any successful partnership. Foster trust by:

Commit to regular performance reviews and post-project assessments to identify improvements. Encourage innovation by:

Be proactive in managing potential disruptions. Effective strategies include:

Tracking key performance indicators (KPIs) helps ensure the partnership remains productive. Focus on metrics such as:

Pioneer Plastics has over 40 years of industry experience as an injection molding partner. Their broad range of capabilities includes custom injection molding, tool building services, and engineering services for plastics.

Pioneer Plastics employs strict quality assurance protocols to ensure every component meets precise specifications, contributing to high performance and reliability.

Their in-house tool building and engineering teams streamline design refinements and enable rapid tool modifications, which can help accelerate production timelines and reduce costs.

With extensive experience in handling complex geometries, Pioneer Plastics delivers custom plastic parts that meet demanding performance standards across diverse industries.

As a U.S.-based supplier, Pioneer Plastics leverages domestic production to potentially offer reduced shipping distances and streamlined communication. These factors can contribute to an efficient and responsive manufacturing environment.

Pioneer Plastics emphasizes an open and collaborative communication style, ensuring that OEMs are kept informed throughout the process. This transparency fosters strong, long-term partnerships built on mutual success.

Dedicated to innovation and process optimization, Pioneer Plastics constantly explores new technologies and methods aimed at enhancing product performance and operational efficiency for OEMs.

Robust OEM injection molding partnerships are fundamental for achieving superior quality, cost efficiency, and accelerated time-to-market. Selecting a supplier with proven expertise, collaborative design support, scalable production capabilities, and transparent communication can lay the groundwork for lasting success.

If you’re ready to reassess your supplier relationships or begin a new project, Pioneer Plastics offers the expertise, flexibility, and reliability you need. Contact Pioneer Plastics today to schedule a consultation and discover how a dedicated injection molding partner can transform your manufacturing processes and elevate your product outcomes.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Plastic molding machines are integral to modern manufacturing, converting raw plastic into finished products using a combination of heat, pressure, and motion. They facilitate the

When we hold plastic parts in our hands, we usually aren’t thinking of how it was manufactured or what machines were used in the process.

Collecting Hot Wheels™ and other diecast cars is a pastime that many of us pick up in childhood. As a child, you mainly want to