Businesses relying on overseas plastic manufacturing are facing a storm of uncertainty. International trade disputes, fluctuating import tariffs, and unpredictable shipping delays can cripple budgets and disrupt operations. What once seemed like a cost-effective solution is now fraught with hidden expenses and logistical nightmares, leaving companies searching for a more reliable alternative. Many are finding […]

Insert molding is an injection manufacturing process that integrates multiple materials into a single, cohesive component. It works by placing a preformed insert—often made of metal, ceramic, or another durable material—into a mold cavity before injecting molten plastic around it. This technique fuses the materials together, creating a robust, unified part that leverages the distinct […]

Injection molding has drastically changed the way everyday items are produced. The process involves melting plastic pellets and injecting them into custom molds to create detailed, consistent products that meet modern standards for durability and design. Thanks to precision engineering, advanced tool building, and skilled craftsmanship, injection-molded items are reliable, lightweight, and safe for daily […]

Understanding the injection molding materials used in production is fundamental to creating high-quality, durable, and functional plastic products. The selection of the right resin influences a product’s performance, appearance, and cost-effectiveness throughout manufacturing. Whether you’re developing a food-safe container or specialized industrial components, each injection molding material offers unique properties that cater to specific applications. Materials […]

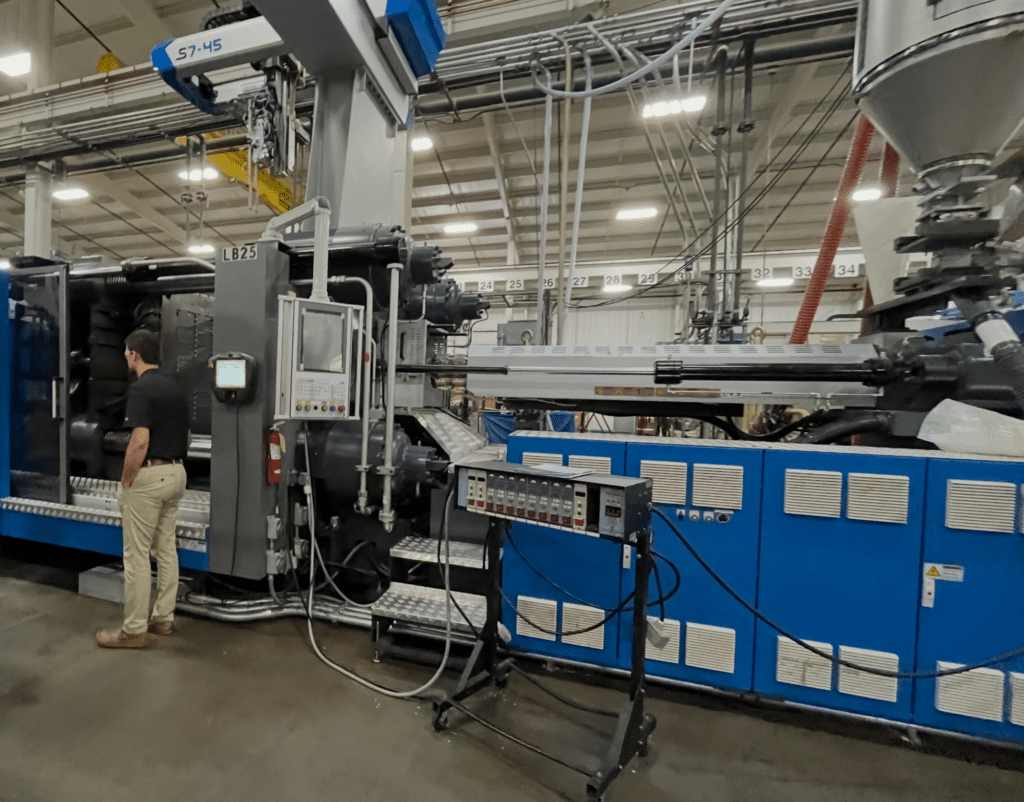

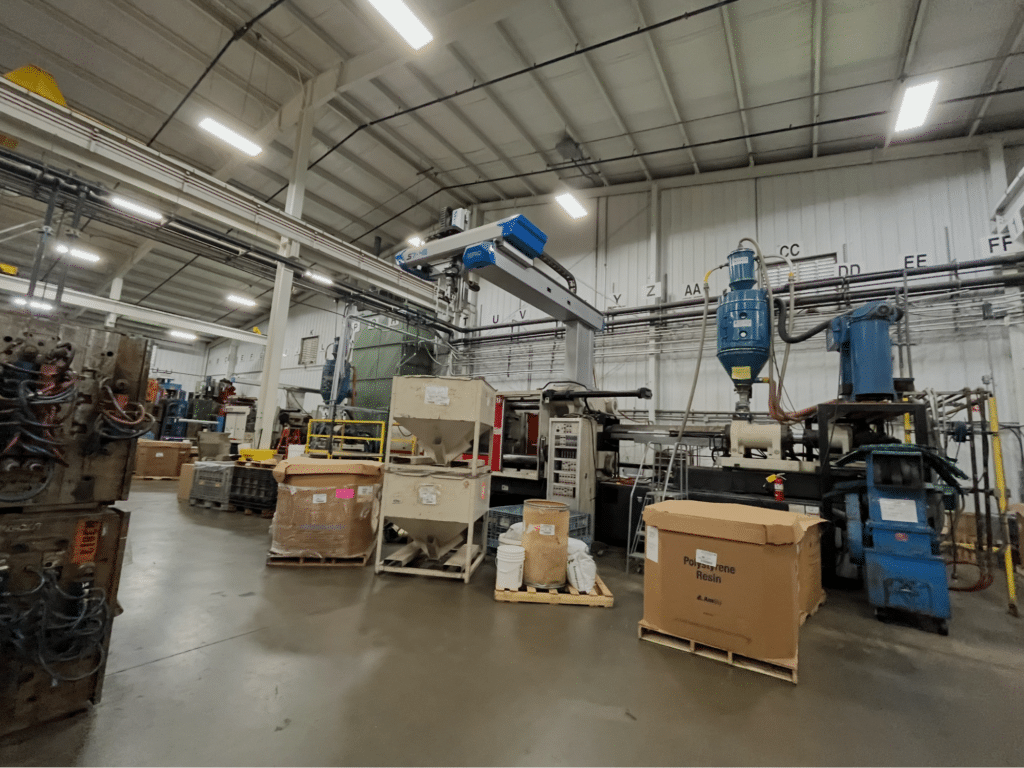

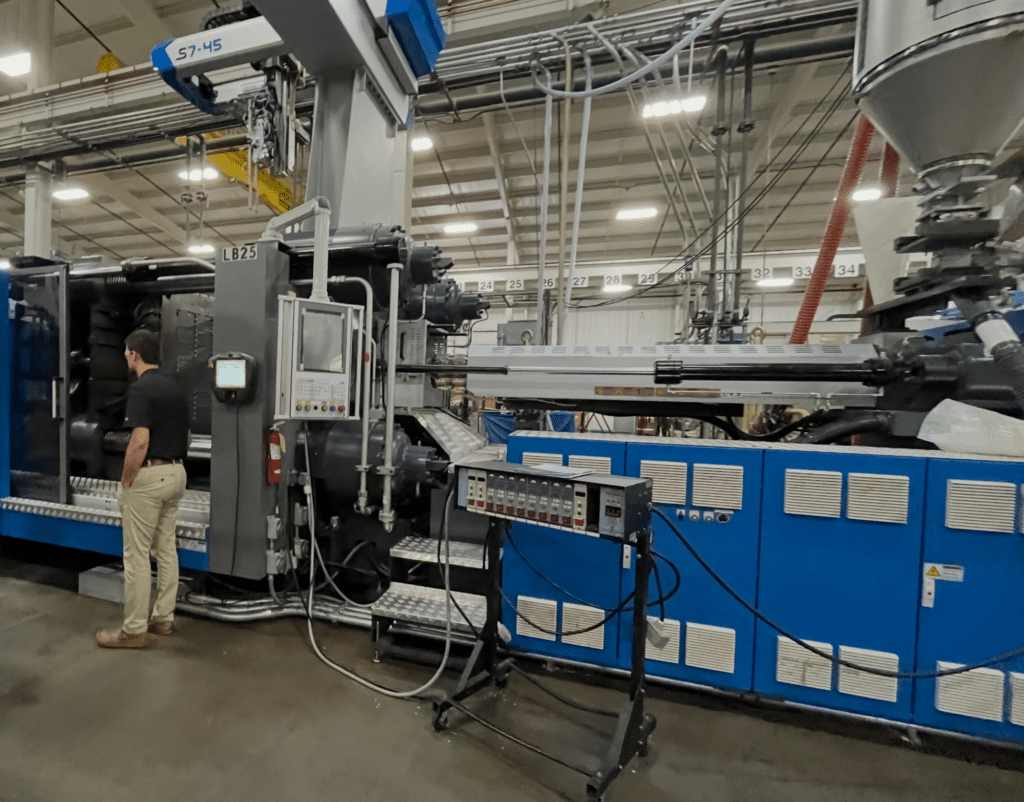

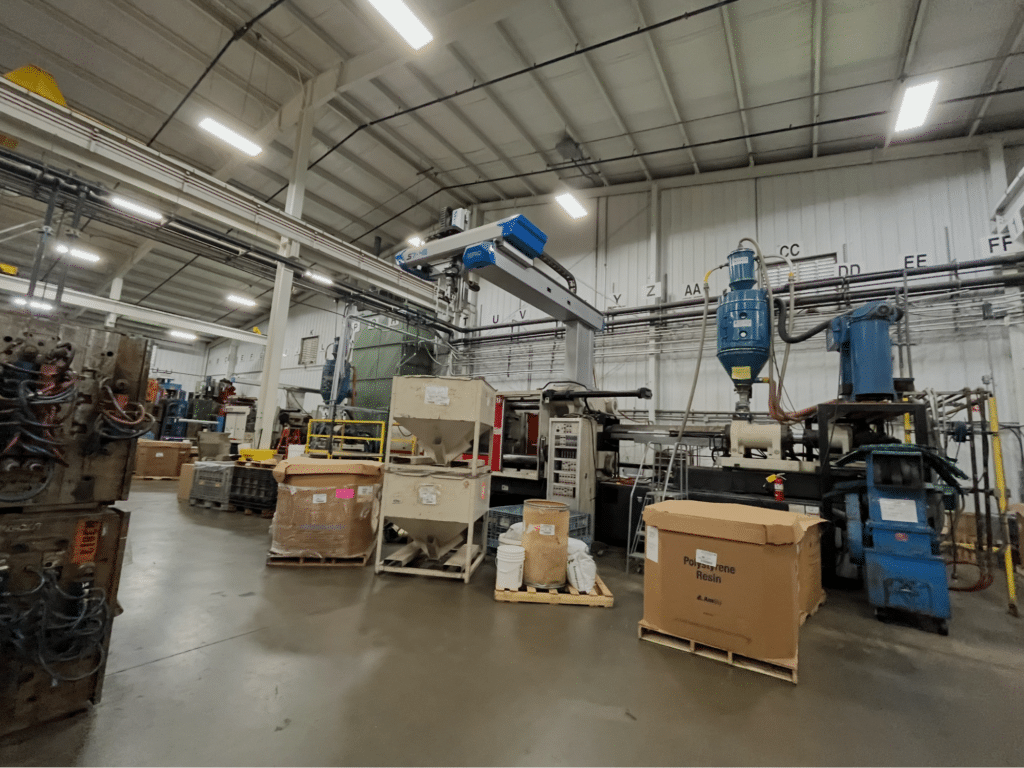

Plastic injection molding is a popular manufacturing method used to produce a wide variety of products across industries. From consumer goods to industrial components, the versatility and cost-effectiveness of plastic injection molding makes it an ideal choice for many manufacturers. However, choosing the right plastic injection molding partner can be challenging. Partnering with the right […]

As the demand for higher-performing plastics mounts, advanced features that enhance product usability and aesthetics are becoming more common. However, integrating undercuts, thin walls, living hinges, and other advanced design elements into high-volume injection molding is no simple task. Successfully molding complex plastic parts requires a deep understanding of design for manufacturability principles, close collaboration between […]

Achieving defect-free, high-performing plastic products requires precision and dedication at every production stage. In plastic injection molding, quality control is essential for ensuring that every part meets strict design and performance standards. By implementing thorough quality control measures from material selection to final packaging, manufacturers can reduce errors, minimize waste, and deliver exceptional products. Pioneer Plastics, […]

Selecting a reliable custom injection molding partner goes far beyond a simple procurement decision—it lays the foundation for product success and business growth. Whether you are a large enterprise or an innovative entrepreneur, finding the right partner is critical. A top manufacturer not only produces high-quality parts but also becomes a strategic ally through tailored […]

Reshoring manufacturing—moving production back to the United States—has emerged as a crucial strategy for reducing operational vulnerabilities, enhancing product quality, and meeting the demand for American-made goods. Global disruptions in recent years have prompted manufacturers to reconsider the stability and advantages of domestic production. Beyond cost considerations, reshoring also helps businesses secure supply chain control, […]

“Made in USA” manufacturing signifies far more than a simple label—it represents a commitment to quality, local economic growth, and ethical production practices. At its core, it refers to goods primarily produced within the United States, where domestic facilities oversee critical aspects of product design, assembly, and labor. For many, this designation is often associated […]

In today’s dynamic manufacturing world, finding a production method that is both efficient and adaptable is crucial for meeting unique customer demands. Custom injection molding excels in delivering precision-crafted plastic components across a wide range of industries. This process enables the creation of highly specific products, from durable industrial parts to sleek display cases for […]

Did you know that over 2 billion plastic parts are produced each year through injection molding? In today’s fast-paced manufacturing landscape, injection molding stands as a cornerstone technology for producing high-quality plastic components efficiently and cost-effectively. Whether for automotive parts, consumer electronics, medical devices, or everyday household items, injection molding enables the mass production of […]