Injection Molding With High Heat Resins

Temperature plays a huge role in the custom injection molding process– even helping to determine the type of resin the part is made from. Resins

Pioneer Plastics, a renowned custom plastic injection molding manufacturer, is located in Dixon, Kentucky. Established with a vision to deliver high-quality and innovative plastic solutions, Pioneer Plastics has been serving a diverse clientele across various industries, including the public sector, consumer goods, and the food service sector. By leveraging cutting-edge technology and expertise, the company has carved a niche for itself as an industry leader in providing customized plastic solutions that address specific business needs.

A testament to its ingenuity is a project involving a global convenience store chain that needed a unique solution in transporting freshly made pizzas from an industrial kitchen to retail outlets without compromising the integrity of the product.

The primary challenge faced by Pioneer Plastics’ customer revolved around designing a transportation system for pizzas that met several critical criteria. The convenience store chain needed a streamlined and efficient way to transport thousands of pizzas daily from their industrial kitchen to various retail locations. The issues at hand included:

1. Product Integrity: Ensuring the pizzas did not get damaged during transit was paramount. This required a stacking system where pizzas would not sit directly on each other, preventing crushing.

2. Cost Efficiency: The initial use of metal pans for stacking proved to be costly and labor-intensive, necessitating a more affordable and practical alternative.

3. Storage and Transport: Post-delivery, an efficient method for returning crates to the kitchen and storing them was needed. The crates had to stack in a way that saved space and facilitated easy return logistics.

Pioneer Plastics addressed these challenges with a series of innovative solutions:

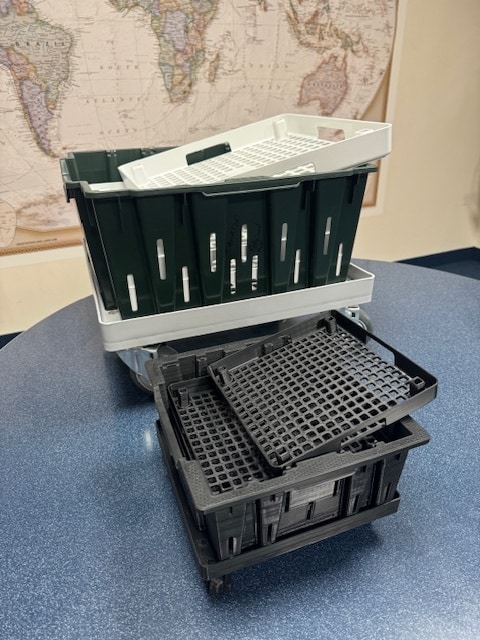

1. Interlocking Crate Design: The team at Pioneer Plastics engineered a state-of-the-art crate system that allowed pizzas to be stacked securely without the risk of damage. Each crate could stack on the one beneath it without touching the pizzas, thus preserving their quality.

2. Revised Tray Design: Given that the initial metal pans were financially unsustainable, Pioneer Plastics devised a unique paper tray system with strategically placed lugs or pegs. These features enabled the pizzas to be inserted snugly within the trays, allowing them to stack while maintaining their shape and form.

3. Nesting Capability: To streamline the crates’ return journey to the kitchen and conserve space, the design allowed for the crates to nest inside each other when not in use. This feature dramatically reduced the volume of the crates, making them easier and more economical to transport back.

The impact of these solutions was significant for the convenience store chain and Pioneer Plastics. By successfully transitioning from metal pans to a paper tray system with interlocking features, the company:

– Preserved Product Quality: The new stacking method ensured pizzas arrived at stores in pristine condition, increasing customer satisfaction and maintaining product quality.

– Reduced Costs: The switch from metal pans to paper trays with innovative lug designs lowered manufacturing and operational costs, providing a more economically viable solution for the client.

– Enhanced Efficiency: Storage and return logistics improved, as the nesting capability of the crates reduced space requirements and streamlined the process, offering both time and cost efficiencies.

Pioneer Plastics exemplifies how a company can harness innovation and technical expertise to overcome industry-specific challenges and deliver customized solutions. This case study highlights the firm’s ability to listen to customer needs, craft bespoke solutions that merge practicality with cost sensitivity, and ultimately drive operational excellence for its partners. Other businesses in the injection molding and food service industries can learn from Pioneer Plastics’ proactive approach, flexibility in design, and commitment to quality. By staying attuned to client challenges and industry dynamics, Pioneer Plastics remains a case study in effective problem-solving and industry leadership.

Temperature plays a huge role in the custom injection molding process– even helping to determine the type of resin the part is made from. Resins

367 million metric tons of plastic were produced in 2020 — a million metric tons less than the record high of 2019. From bottles and

Whether you’re about to ramp up existing production or add a new product line, you’re probably experiencing a mixture of excitement and apprehension. You may