Key Considerations for Choosing a Plastic Injection Molding Partner

Plastic injection molding is a popular manufacturing method used to produce a wide variety of products across industries. From consumer goods to industrial components, the

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

Stop letting unreliable suppliers and supply chain delays derail your project. We deliver high-quality, American-made plastic parts from our facility in Kentucky.

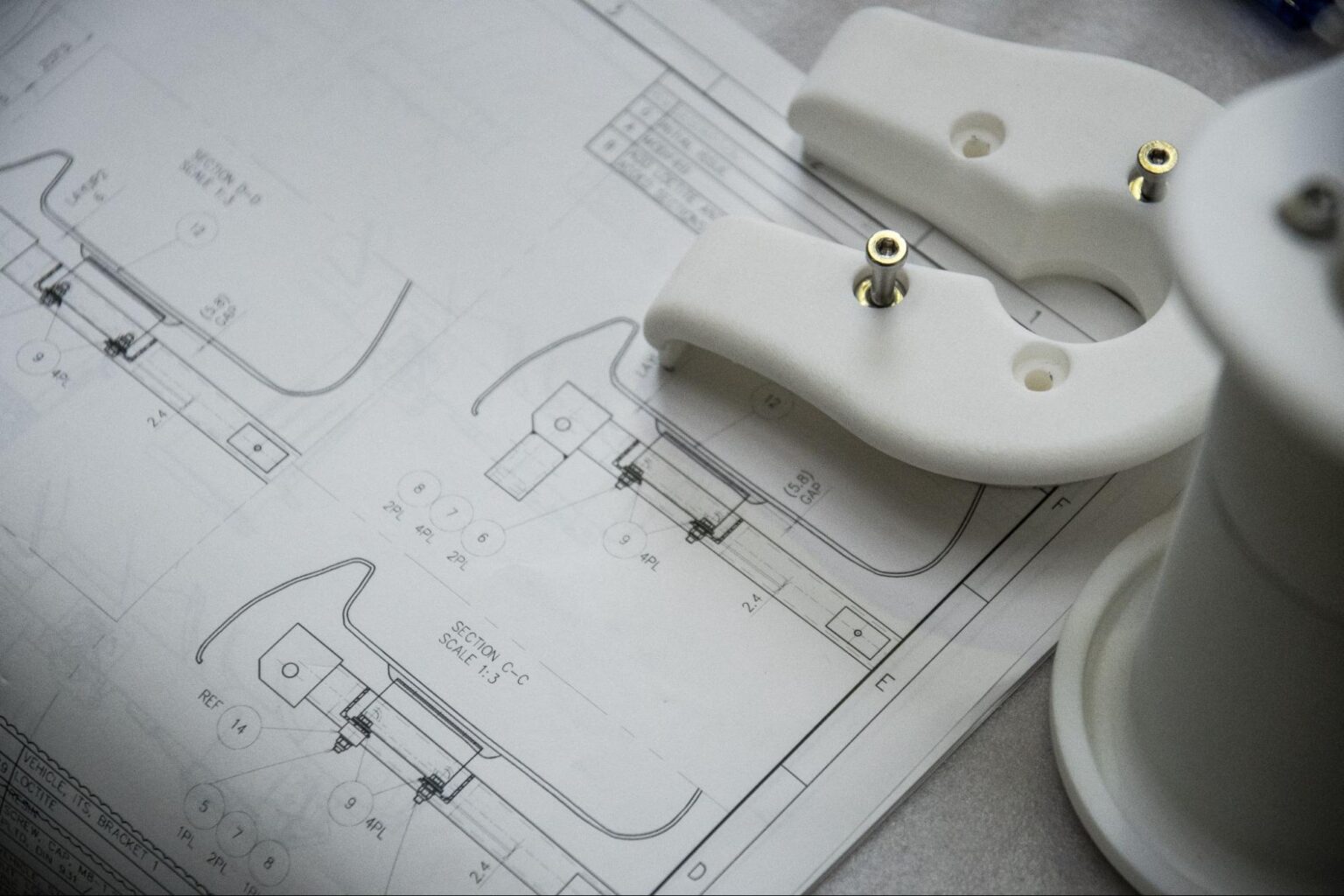

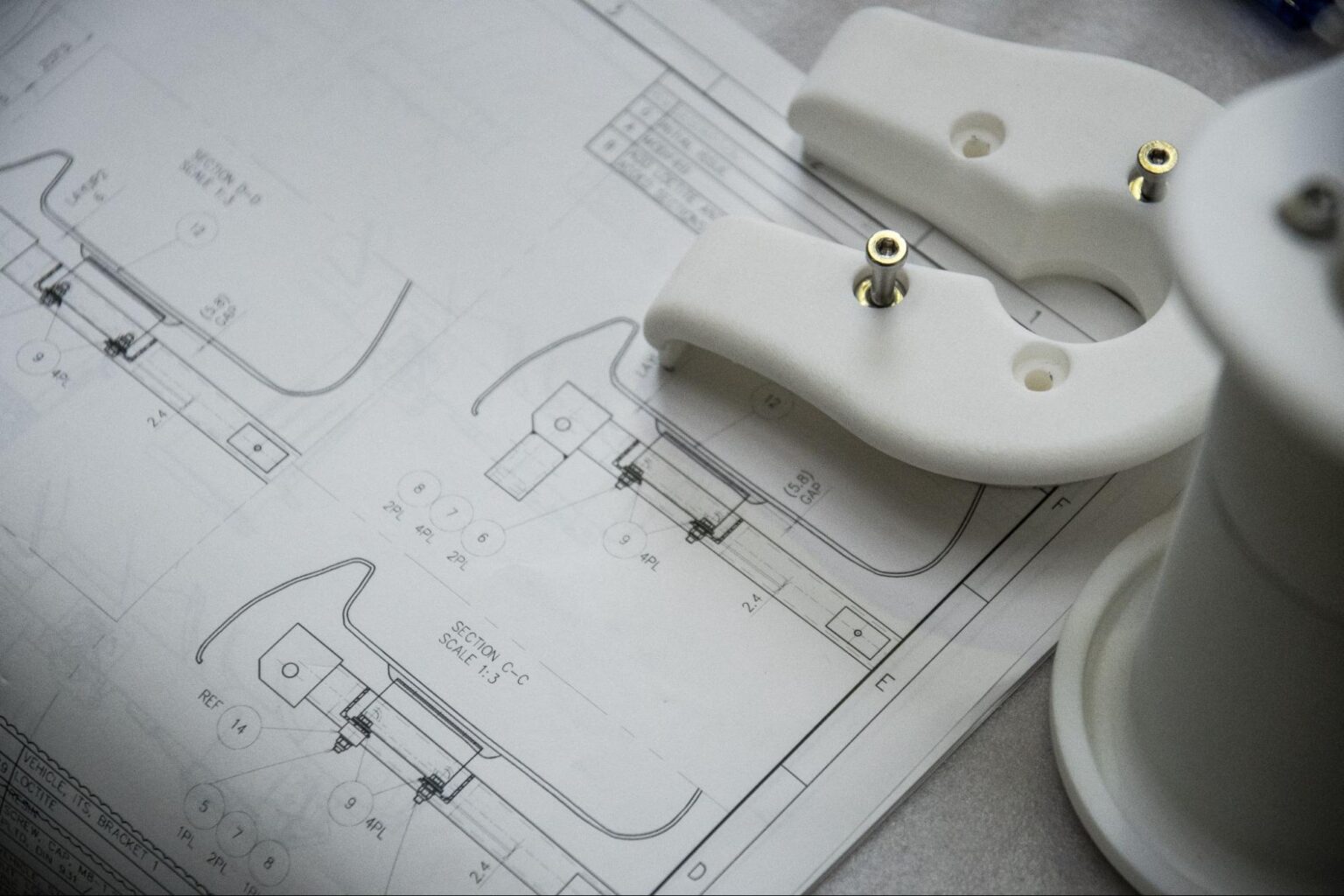

Provide your part design or idea. Our engineering team reviews requirements and highlights the most cost-effective path.

We help polish your design, build a precision mold, and confirm pricing, timeline, and specs—no surprises later.

Your parts are manufactured with rigorous quality control and clear, milestone-based updates.

Get finished parts shipped to your door, on your schedule. Avoid overseas delays and keep your project moving.

This is the same proven process used by top brands like GE, Whirlpool, and Pizza Hut to keep supply chains running and projects profitable.

Choosing the right material is critical to your project’s success. Our engineering team, with over 175 years of combined experience, doesn’t just make parts—we partner with you to select the perfect material for your specific application, ensuring performance, durability, and cost-effectiveness.

This is your solution for OEM-level, high-volume production. Schedule a free, no-obligation project review with our engineering team today. We’ll provide a clear plan and transparent pricing for your commercial-scale project.

Custom injection molding involves significant up-front costs, typically ranging from $10,000 to $250,000, influenced by the size and complexity of the mold. If your project involves producing 1,000 units or fewer, alternative manufacturing methods may be more cost-effective. For more information on our engineering process and mold pricing, see our Custom Injection Molding page.

Most molds take 8–12 weeks to design, engineer, and build depending on the part’s complexity and production requirements. Once your mold is complete, we deliver samples for your approval before beginning full production. Throughout, you’ll receive clear timelines and proactive updates, so you know exactly what to expect.

Reshoring your molding projects to the USA reduces risks of overseas shipping delays, quality inconsistency, and communication breakdowns. At Pioneer Plastics, our US-based team in Kentucky delivers responsive project management and American-made reliability—ensuring your parts arrive on time and meet your quality standards. Learn more about our US manufacturing and quality standards.

We maintain strict quality control throughout the manufacturing process—starting with design and mold building, all the way through production and finishing. Each part is inspected to ensure it meets your exact specifications, and our experienced team monitors production for consistency across every run. Decades of experience and rigorous standards mean you can trust every shipment. Discover how our in-house tooling management benefits your long-term supply chain.

Absolutely. Your mold is stored and maintained at our secure facility between production runs. Our in-house team inspects, cleans, and, if needed, services your mold so it stays in top condition, ready for your next order. This preserves mold life and ensures consistent, precise results for your future projects.

Look for proven experience, in-house tooling capabilities, strong quality assurance, transparent project management, and a track record with major brands. At Pioneer Plastics, we offer 40+ years serving high-profile clients like GE, Whirlpool, Pizza Hut, and Hobby Lobby—delivering U.S.-made reliability, engineering expertise, and responsive service. See how we support industries like appliances, retail, and food packaging.

For an accurate review, please provide your part design or drawing (if available), estimated annual quantities, required material type, any special features, and your anticipated timeline or launch date. The more detail you share, the faster and more precisely we can deliver your quote and production plan.

Plastic injection molding is a popular manufacturing method used to produce a wide variety of products across industries. From consumer goods to industrial components, the

In the world of manufacturing, efficiency, cost-effectiveness, and quality are key. This is where hot runner systems in injection molding come into play, revolutionizing the

When we hold plastic parts in our hands, we usually aren’t thinking of how it was manufactured or what machines were used in the process.