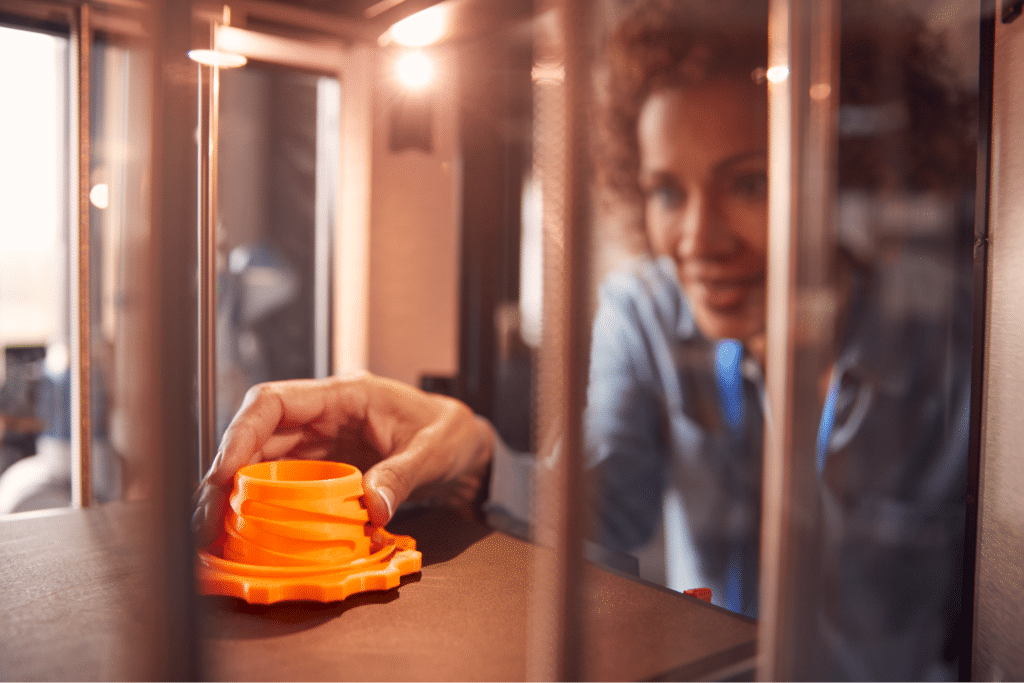

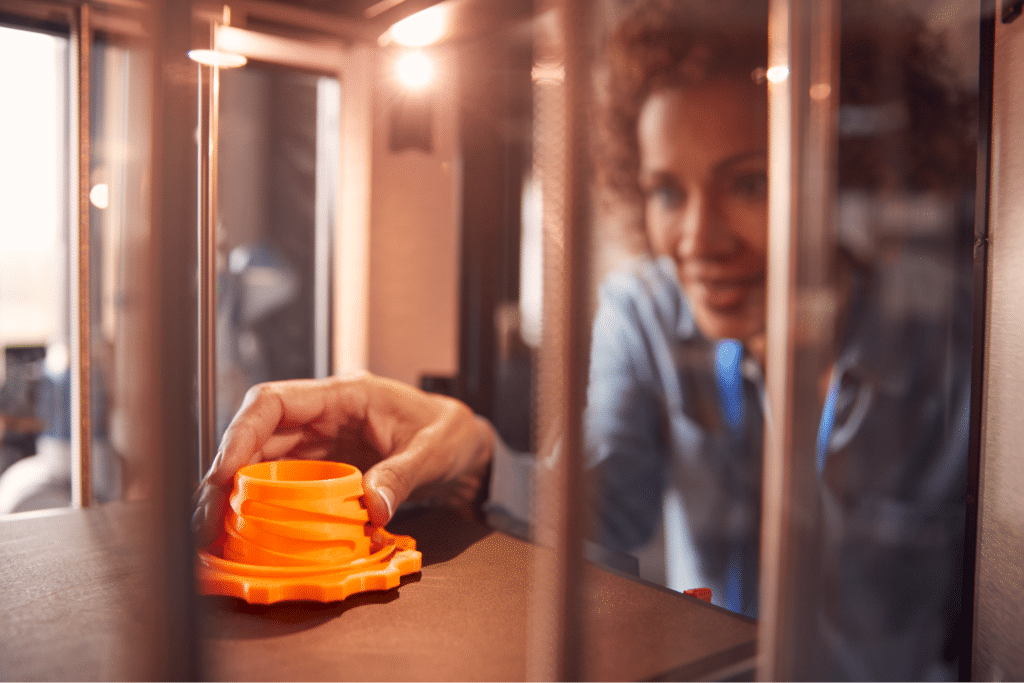

3D printing is revolutionizing manufacturing by offering unmatched versatility and creative freedom. When paired with the established efficiency and precision of injection molding, businesses can benefit from improved production workflows, potential cost reductions, and enhanced quality. This integrated approach blends the speed and flexibility of rapid design refinement with the high-volume reliability of injection molding. […]

“Made in USA” manufacturing signifies far more than a simple label—it represents a commitment to quality, local economic growth, and ethical production practices. At its core, it refers to goods primarily produced within the United States, where domestic facilities oversee critical aspects of product design, assembly, and labor. For many, this designation is often associated […]

In today’s fast-paced product development landscape, quickly transforming ideas into reality is crucial for innovation. Prototype injection molding and production-scale injection molding are essential for designing, testing, and manufacturing plastic parts, though they serve different purposes. This guide explores the distinct roles of both methods, highlighting their applications, benefits, and advancements. Understanding these differences can help businesses, […]

Pioneer Plastics, renowned for their bespoke injection plastics molding solutions, has been serving a diverse clientele for over 40 years. With a mission to deliver innovative, high-quality plastic products, Pioneer Plastics aims to collaborate with industries to provide customized solutions that meet precise client specifications. Challenge Among the myriad challenges Pioneer Plastics faces is the […]