What’s the Best Way to Protect Your Collectibles?

Whatever you collect, from books to memorabilia to antiques, protecting your collectibles should be a top priority. If you have a home full of one-of-a-kind

DISCOVER OUR NEWLY RELEASED COLLECTIBLE DISPLAY CASES! SHOP NOW

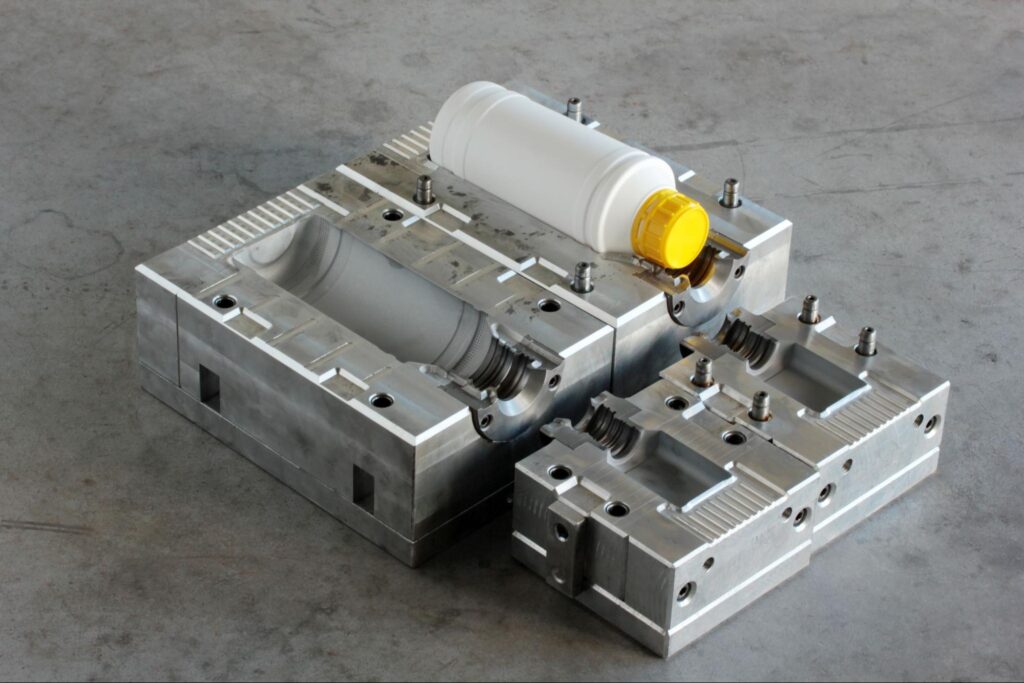

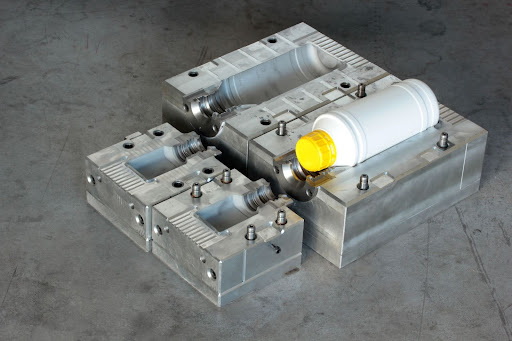

When it comes to sourcing molds for plastic injection molding, many companies are attracted to the perceived cost savings and faster production times promised by overseas mold makers. However, the reality is that working with domestic companies offers many advantages that can easily outweigh any short-term benefits of outsourcing. From hidden expenses to quality concerns and intellectual property risks, the consequences of using overseas suppliers can often lead to higher costs and headaches down the road.

In this article, we explore seven eye-opening truths that highlight the critical advantages of partnering with U.S.-based mold makers. By uncovering these factors, you’ll gain a deeper understanding of why American companies deliver superior value in terms of quality, consistency, and peace of mind. If you prioritize efficiency, precision, and long-term ROI, these surprising truths will help guide you toward a more secure and reliable mold-making solution.

Lower upfront prices for overseas molds may seem appealing, but these “savings” can quickly evaporate. Shipping complexities, fluctuating fuel costs, and import tariffs all add unexpected fees. Even seemingly simple changes—like design modifications—can become costly when factoring in extended communication cycles and potential logistics hurdles.

In addition, companies may need extra travel for quality control or pay higher rates for on-the-ground inspections. Should the mold require significant rework or fail to meet strict tolerance requirements, those initial savings often give way to longer-term expenses.

By contrast, American mold makers typically provide transparent pricing, consistent production standards, and reliable engineering support that help you avoid budget surprises down the road. Likewise, American mold makers may have relationships with overseas suppliers that they have worked with in the past and trust. This relationship can eliminate these complexities while still allowing your business to reap the benefits of lower initial costs through overseas production.

It’s a common misconception that overseas mold makers can easily match domestic delivery schedules. In reality, extended transit routes, customs clearance, and potential geopolitical factors can all cause delays. Ocean freight alone can take weeks—or even months—to arrive, while air freight, though faster, carries hefty premium costs and capacity limitations.

Time zone differences further complicate production coordination, as immediate feedback and problem-solving become cumbersome.

By choosing a U.S.-based mold maker, you minimize these logistical barriers. Shorter shipping distances, fewer customs bottlenecks, and faster communication cycles help keep your projects on track and aligned with critical deadlines.

Outsourcing mold production abroad can expose your product designs and trade secrets to legal systems that may have weaker safeguards on intellectual property. While many suppliers do respect NDAs, inconsistent enforcement in some jurisdictions leads to higher chances of unauthorized replication or misuse. The potential loss of proprietary data could compromise your competitive edge.

By partnering with domestic mold makers, you operate within a legal framework that prioritizes strong IP protection. Strict contractual agreements and intellectual property safeguards help ensure your designs remain secure, even in scenarios where the molds are made overseas through a partnership with a domestic custom injection molding company.

Precision in mold making is non-negotiable. Even minute deviations can result in production delays or subpar parts. Some suppliers overseas offer robust checks, but it’s not uncommon to encounter varying manufacturing standards, inconsistent inspection methods, and communication gaps that hamper rigorous oversight.

U.S.-based mold makers typically offer in-house tooling but will also work with overseas mold suppliers who employ uniform inspection procedures, advanced measurement equipment, and established quality control protocols that align with American industry benchmarks.

This commitment to excellence not only minimizes defect rates but also extends the mold’s lifespan. Investing in a partner who strives for superior quality from the start means fewer headaches, lower scrap rates, and a smoother overall production cycle.

High-quality mold creation demands close collaboration between the client’s engineering team and the mold manufacturer. The ability to address design changes, troubleshoot unforeseen issues, and refine specifications in real time is a major advantage of working domestically. With fewer time zone hurdles and a shared language, design tweaks or manufacturing adjustments can be dealt with efficiently.

In addition, U.S.-based mold makers often have deep familiarity with American regulations, best practices, and local manufacturing requirements. This intimate understanding fosters a smoother flow of ideas, whether the mold is made in the U.S. or overseas, leading to improvements in mold design and performance.

Strong alignment between engineering and production plays a critical role in driving successful project outcomes. Partnering with a team experienced in collaborating closely with engineering and design professionals to bring product concepts to life is a major asset. When working with an overseas mold maker, having a U.S.-based partner involved from design through to production ensures a more efficient and cost-effective process.

A mold’s value extends well beyond its initial build. Over time, repairs, routine tune-ups, or part replacements may become necessary to keep production running smoothly. Many overseas suppliers offer limited after-sale service, and returning a faulty mold for repairs can lead to extended downtimes and steep shipping fees.

With a domestic mold maker, you gain prompt access to tool development, maintenance and support services. Local expertise and comprehensive repair options help avoid prolonged production outages.

As Forbes describes, effective after-sale strategies protect uptime and reduce operational unpredictability. This ensures your mold remains a productive asset for as long as you need it.

One overlooked factor in mold sourcing is the possible damage to a company’s brand reputation. Frequent delays, product quality lapses, or substandard mold performance can erode trust among customers and stakeholders. In industries such as food packaging, medical devices, or aerospace, even minor defects can trigger costly recalls, fines, or public scrutiny.

According to Business.com, brand perception hinges on consistent product quality and reliability. When you choose a U.S.-based manufacturer, you ensure tighter control over these influences, reducing the likelihood of setbacks that might jeopardize your hard-earned reputation. Consumers also increasingly reward businesses that emphasize ethical sourcing and domestic production, giving you a competitive edge.

While offshore mold makers may promise lower initial costs, the hidden risks—ranging from shipping delays and uncertain IP enforcement to unpredictable quality—can undermine any upfront advantages. Even if many overseas molds meet reasonable standards, the unpredictable factors often outweigh the supposed benefits.

On the other hand, partnering with American mold makers offers transparent pricing, dependable lead times, secure intellectual property, and ongoing engineering support. This domestic approach ensures higher-quality molds, reduced production downtime, and a stronger brand reputation. By evaluating the total cost of ownership rather than focusing only on short-term discounts, you position your organization for long-term growth and success.

If you’re ready to take the next step in achieving dependable, high-quality plastic injection molding solutions, contact Pioneer Plastics today. We offer rapid prototyping, mold design and building through our in-house tooling, or we can manage the development of the build with trusted tool shops overseas if that is a better fit. All products go through a rigorous quality control inspection process so your final product is ready for shipment directly to you, your consumers, or your retail partners.

The information provided in this content is for general informational purposes only and should not be considered professional advice. It is advisable to consult with a qualified industry professional before taking any action based on this information. The team at Pioneer Plastics is here to assist you with any questions you may have.

Whatever you collect, from books to memorabilia to antiques, protecting your collectibles should be a top priority. If you have a home full of one-of-a-kind

DIXON, Kentucky – Pioneer Plastics has been named Pizza Hut’s STAR Award recipient for Overall Supplier of the Year, as well as Equipment/Smallwares Supplier of

Tooling transfers involve relocating molds from one production facility to another—a critical process for Original Equipment Manufacturers (OEMs) looking to optimize supply chains, enhance quality,