Injection mold tooling is the cornerstone of efficient injection molding operations. A well-maintained mold is essential to achieving high product quality, reducing downtime, and cutting costs. For OEMs, engineers, plant managers, and procurement professionals, mastering mold maintenance is a strategic advantage that directly improves operational performance. This guide provides a focused overview of mold tooling […]

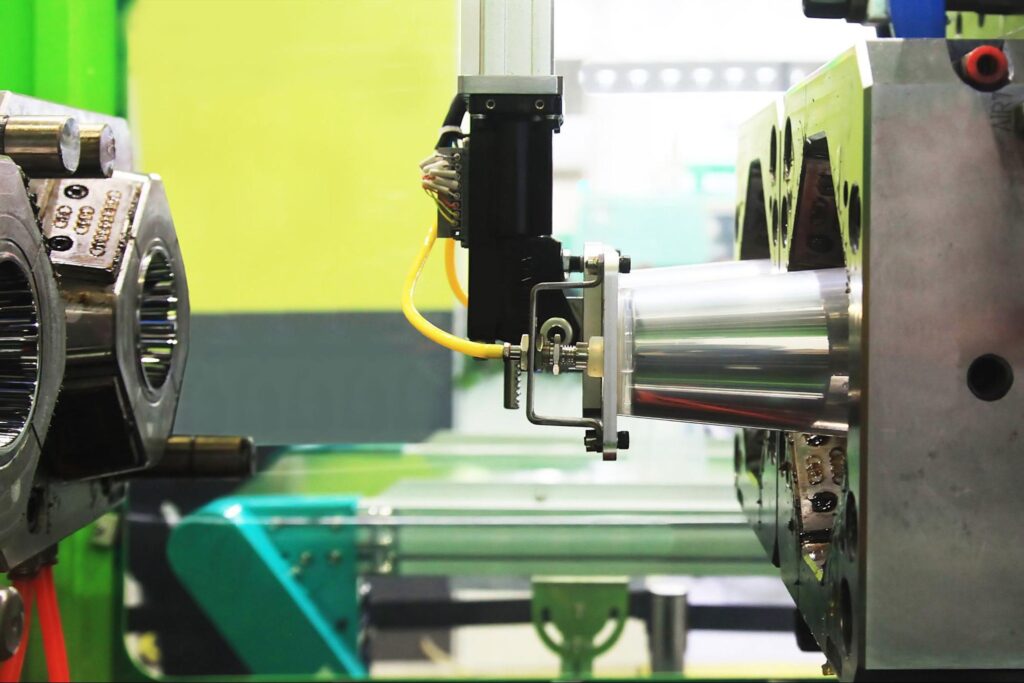

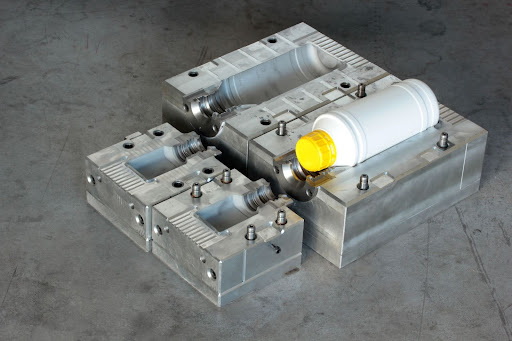

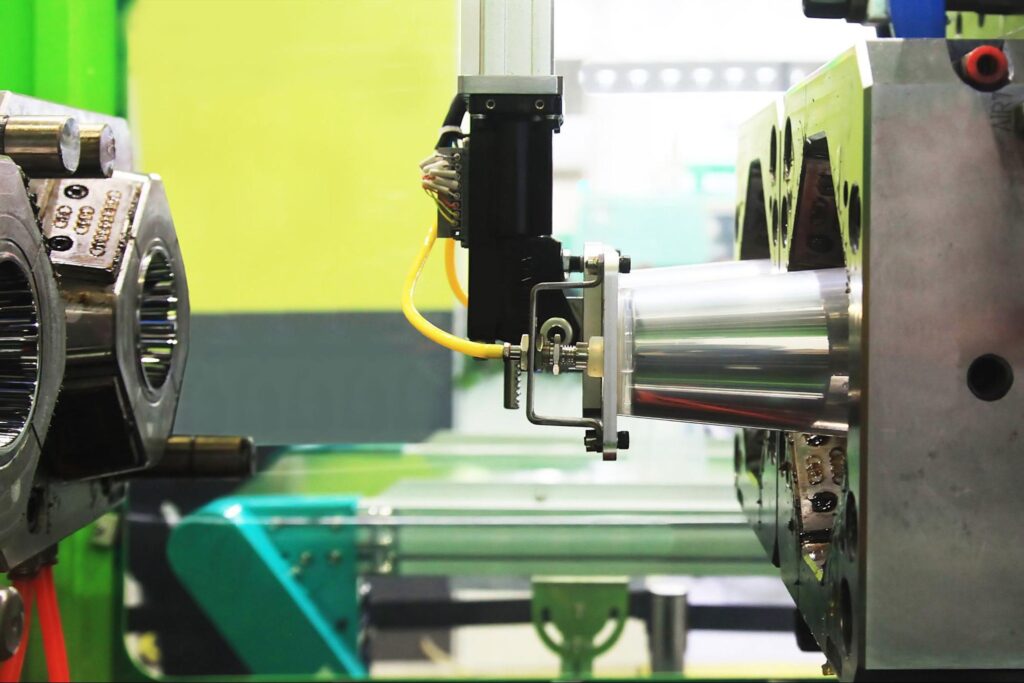

Tooling is the backbone of plastic injection molding. It involves creating molds, dies, and other specialized equipment that transform molten thermoplastic into precise, high-quality components. When tooling in manufacturing is substandard, issues such as warping, shrinkage, and dimensional inconsistencies can arise, wasting materials and delaying production. In contrast, precision-engineered tools improve consistency, reduce waste, and […]

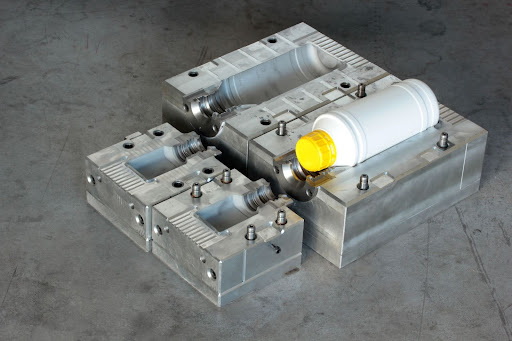

Tooling transfers involve relocating molds from one production facility to another—a critical process for Original Equipment Manufacturers (OEMs) looking to optimize supply chains, enhance quality, or reshore production. Poor planning can lead to delays, hidden costs, and quality risks. This guide explains key factors for successful tooling transfers, outlines the true costs involved, highlights common […]

In industries reliant on plastic components, the success of a project often hinges on the efficiency and precision of the manufacturing process. At the heart of this is strategic mold relocation—a critical step that involves relocating molds from one production facility to another. Whether driven by strategic realignment, capacity expansion, reshoring, or quality improvement, a well-managed […]