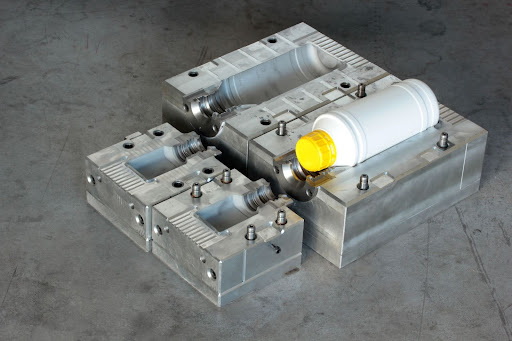

Injection Mold Tooling Maintenance: Ultimate Guide for Efficiency

Injection mold tooling is the cornerstone of efficient injection molding operations. A well-maintained mold is essential to achieving high product quality, reducing downtime, and cutting